- Home

- testo 175 H1

testo 175 H1 - Temperature and humidity data logger

0572 1754testo 175 H1 - Temperature and humidity data logger

0572 1754

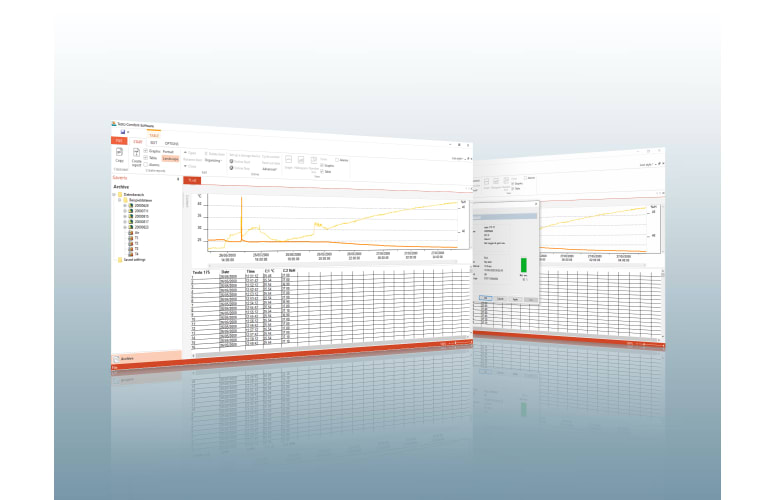

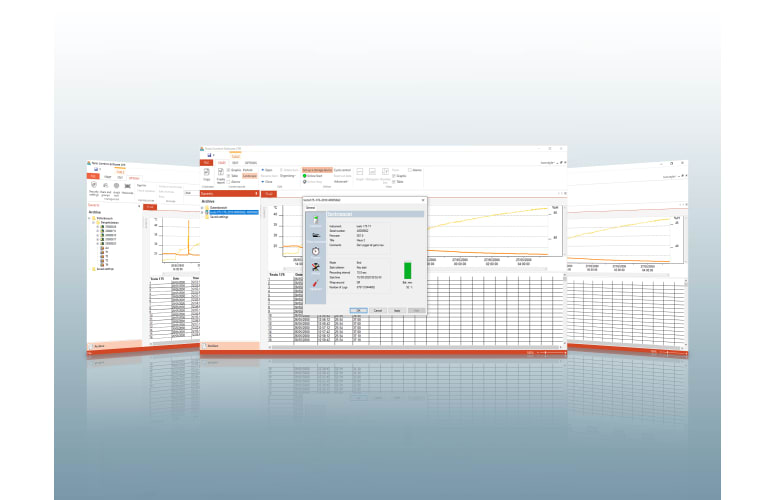

Professional software with Excel export function for programming the logger and data analysis.

The logger comes with an external humidity sensor (stub) for shorter reaction times and a lock to prevent it from being easily stolen or tampered with.

In addition to the current temperature and humidity values, the logger can also log and display dew point values. Other information including adjustable threshold values, breached thresholds and remaining battery power can also be read off the large, clear display.

Security and comfort on all levels

The data logger testo 175 H1 ensures a high level of data security and reliable measurements based on leading-edge technology. It has a super-size memory that can save up to 1 million readings and an extended battery life of up to 3 years. This gives you the freedom to read out the data at longer intervals, even when the measuring cycles are shorter. The triple AAA batteries included in the scope of supply can be easily replaced by the user.

Programming and Analyzing the data Loggers

Choose 1 of 3 software versions to program or read out the loggers or to analyze the measuring data you have obtained on your PC:

- Software ComSoft Basic– included – allows you to program your logger and analyze the data quickly and easily

- Software ComSoft Professional– optional – provides you with additional possibilities and a more detailed analysis of the temperature and humidity values

- Software ComSoft CFR 21 Part11– optional – ideal for the special demands of the pharmaceutical sector in compliance with 21 CFR Part 11

You will need a USB cable (not included in scope of supply) to program your data logger. The data can be transferred to your PC either via USB cable or SD card. Both are optionally available as accessories which can be ordered along with your testo 175 H1.

Temperature - NTC

| Measuring range | -20 to +55 °C |

|---|---|

| Accuracy | ±0.4 °C (-20 to +55 °C) ±1 Digit |

| Resolution | 0.1 °C |

Humidity - Capacitive

| Measuring range | 0 to 100 %RH* |

|---|---|

| Accuracy | < ±1 %RH / year drift at +25 °C ±2 %RH (2 to 98 %RH) at +25 °C ±0.03 %RH/K ±1 Digit |

| Resolution | 0.1 %RH |

| * Not for condensing atmospheres. | |

Dewpoint (calculated)

| Measuring range | -40 to +50 °Ctd |

|---|---|

| Accuracy | +0.03 %RH/K ±1 Digit |

Accessories

0449 0047

0515 0009

0515 0042

0520 0153

0520 0261

0554 1702

0554 1704

0554 1705

0554 8803

0572 0580

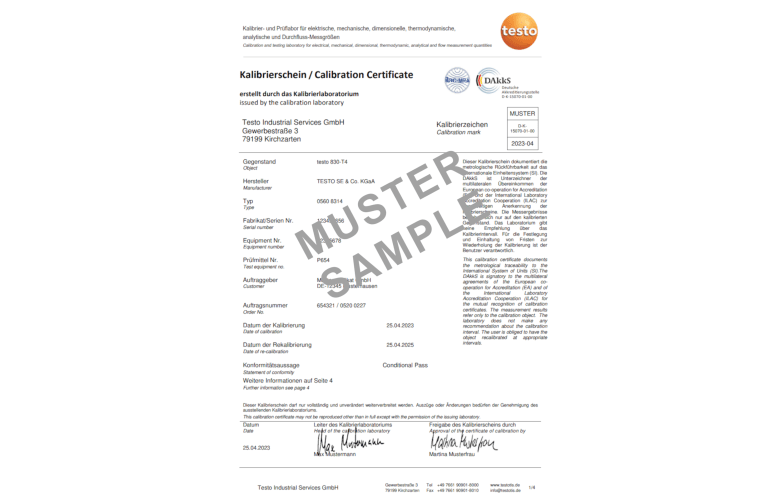

Certificates

0520 0076

0520 0246

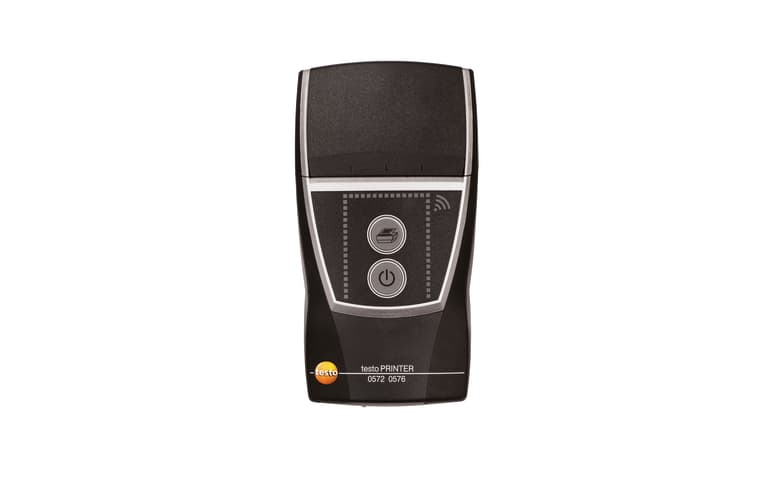

Printer and accessories

0572 0576

Monitoring and documentation of building air conditioning

Temperature and relative humidity are crucial factors in assessing air quality and levels of comfort in indoor spaces, e.g. in workplaces. With the aid of data loggers, this data can be permanently monitored and documented.

They are also excellently suited to the monitoring of ventilation systems or for assessing existing building moisture.

With the use of special software, the measurement configurations can be customised and recorded measurement data can be both analysed and stored.

Monitoring and documentation of the storage temperature and humidity

The proper observance of storage temperature and humidity is an important prerequisite for the quality control of many products; e.g. in the area of food and pharmaceutical products.

To this end data loggers are usually used. They monitor and document the course of ambient conditions automatically, thereby contributing significantly to verifying that product quality is being maintained.

The direct display of violations of limit values allows fluctuations in temperature and humidity to be responded to fast. With the aid of the configuration and read out software, custom measurement configurations can also be made and recorded measurement data can be both analysed and stored.

Monitoring and documentation of the transportation temperature and humidity

The smooth recording and documentation of measurement data plays a significant role for all products that are sensitive to temperature and humidity fluctuations, or which need to be stored in a predesignated area.

The wrong conditions during transportation can result in major losses in quality right through to a complete loss of value for the monitored products.

With the aid of a data logger, goods in transit can be monitored to make sure specified temperature and humidity zones are being observed; this can then be read out, analysed and stored using special software.

- Data sheet testo 175 H1(pdf, 267.2 kB)

- TESTOsolutions identifying damp walls and avoiding mould(pdf, 705.66 kB)

- Instruction manual testo 175-T1. -T2. -T3. -H1(pdf, 1.13 MB)Instruction manual testo 175-T1. -T2. -T3. -H1

- Firmware testo 175 H1(v2.27, 4.13 MB)

- testo usb driver - Instruction manual(pdf, 676.7 kB)

- ComSoft Basic Instruction manual(pdf, 868.78 kB)

- testo usb driver - for various measuring instruments(v2.9.1, 2.02 MB)USB driver for the following devices with USB port: * USB Interface testo 174 / 177 - T + H * testo 300 / 320 / 330 / 330i / 335 / 340 / 350 * testo 435 * testo 556 / 560 / 570 / 580 * testo 635 * testo 735 * testo 845