Discover all the features of the testo 885 thermal imager

- Detector size 320 x 240 pixels: with 76,800 temperature measuring points, measurement objects are captured extremely clearly and accurately in outstanding image quality

- SuperResolution Technology to 640 x 480 pixels: this feature takes the image quality to the next level – making the resolution of the thermal images four times higher

- Integrated digital camera with power LEDs: ideal for assigning thermographic images to real images and thus for creating perfect documentation for customers

- User-friendly operation: ergonomic rotating handle and rotatable, fold-out display

- You can also choose to save thermal images as JPEGs

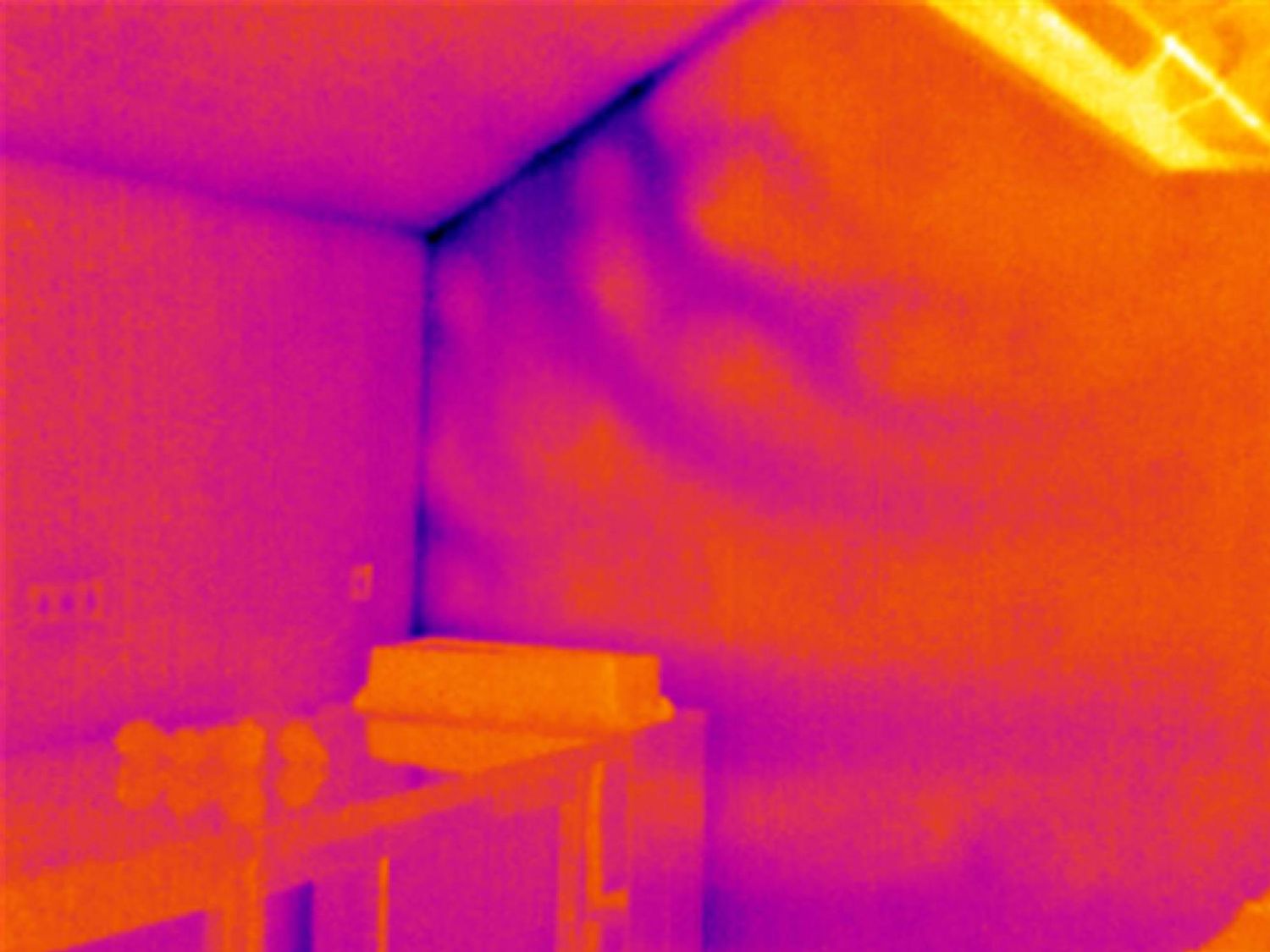

Practical features of the thermal imager specially for building thermography

- Large field of view thanks to 30° lens: with the standard wide-angle lens, large image sections are immediately recognized and the temperature distribution of the measurement object recorded at a glance

- Panorama image assistant: in the case of large measurement objects, the panorama image assistant enables analysis and documentation of the measurement with an overall image compiled from multiple individual images. So there is no need to manage, view and compare a large number of images, which can be laborious. It enables images of entire building shells

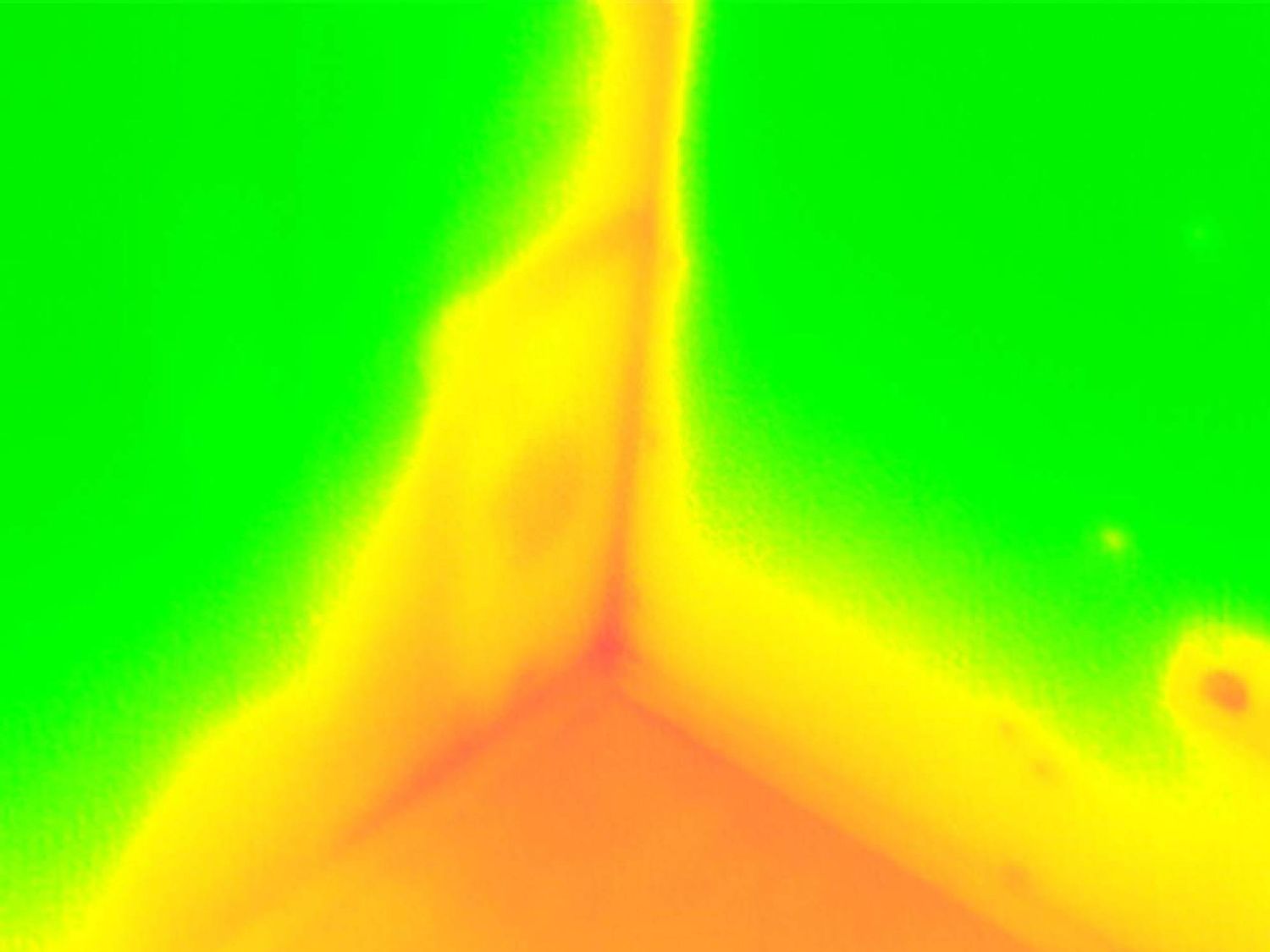

- Special measuring mode for detecting areas susceptible to mould: the dewpoint in the room is calculated by manually entering the ambient temperature and humidity. The dewpoint is then compared with the surface temperature value measured by the camera. Traffic light colours shown on the display (red, yellow, green) then enable readout of the mould risk. The optional radio humidity probe makes things easier: automatic transmission of readings means that manual input of humidity and ambient temperature is no longer needed

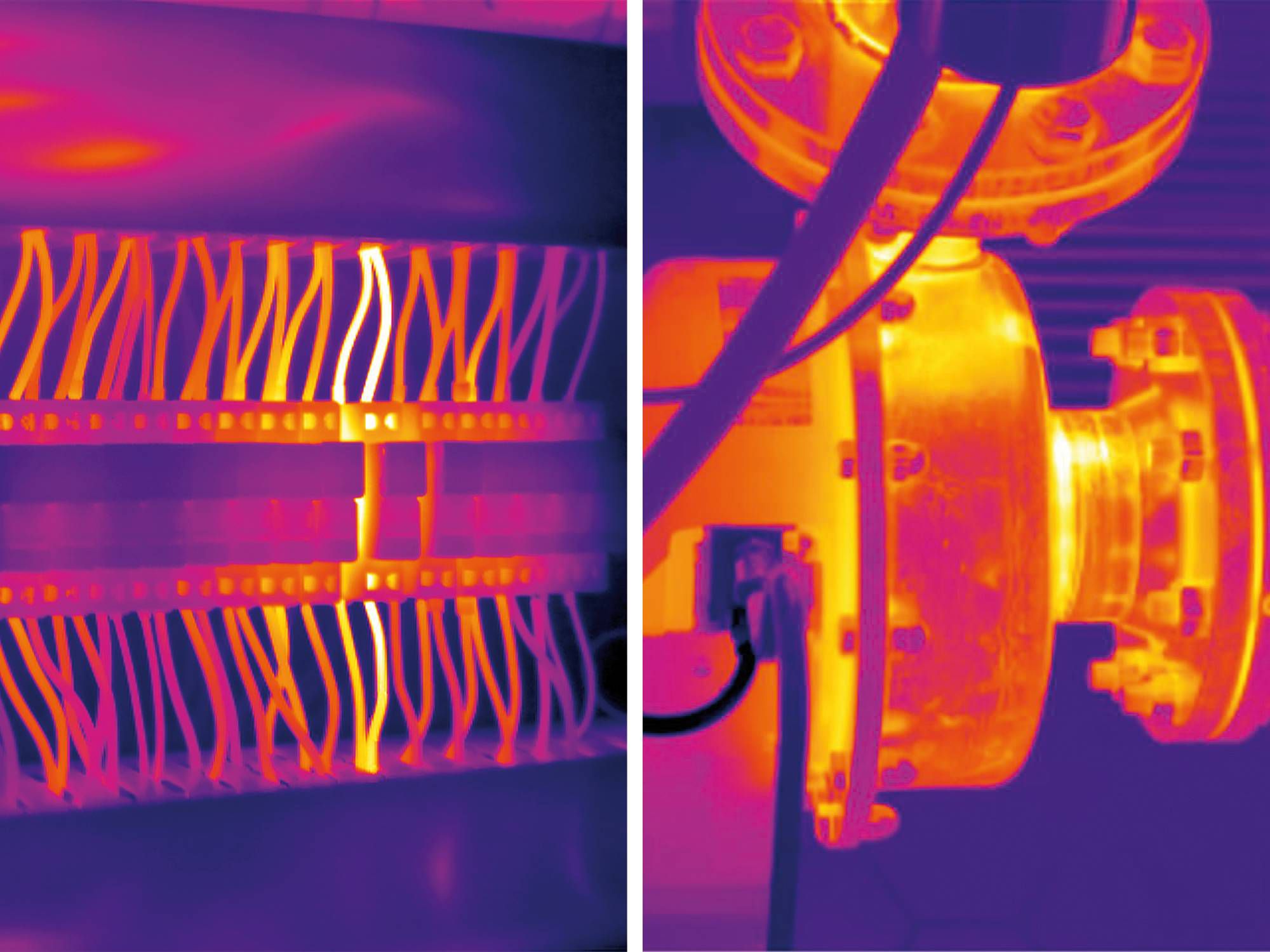

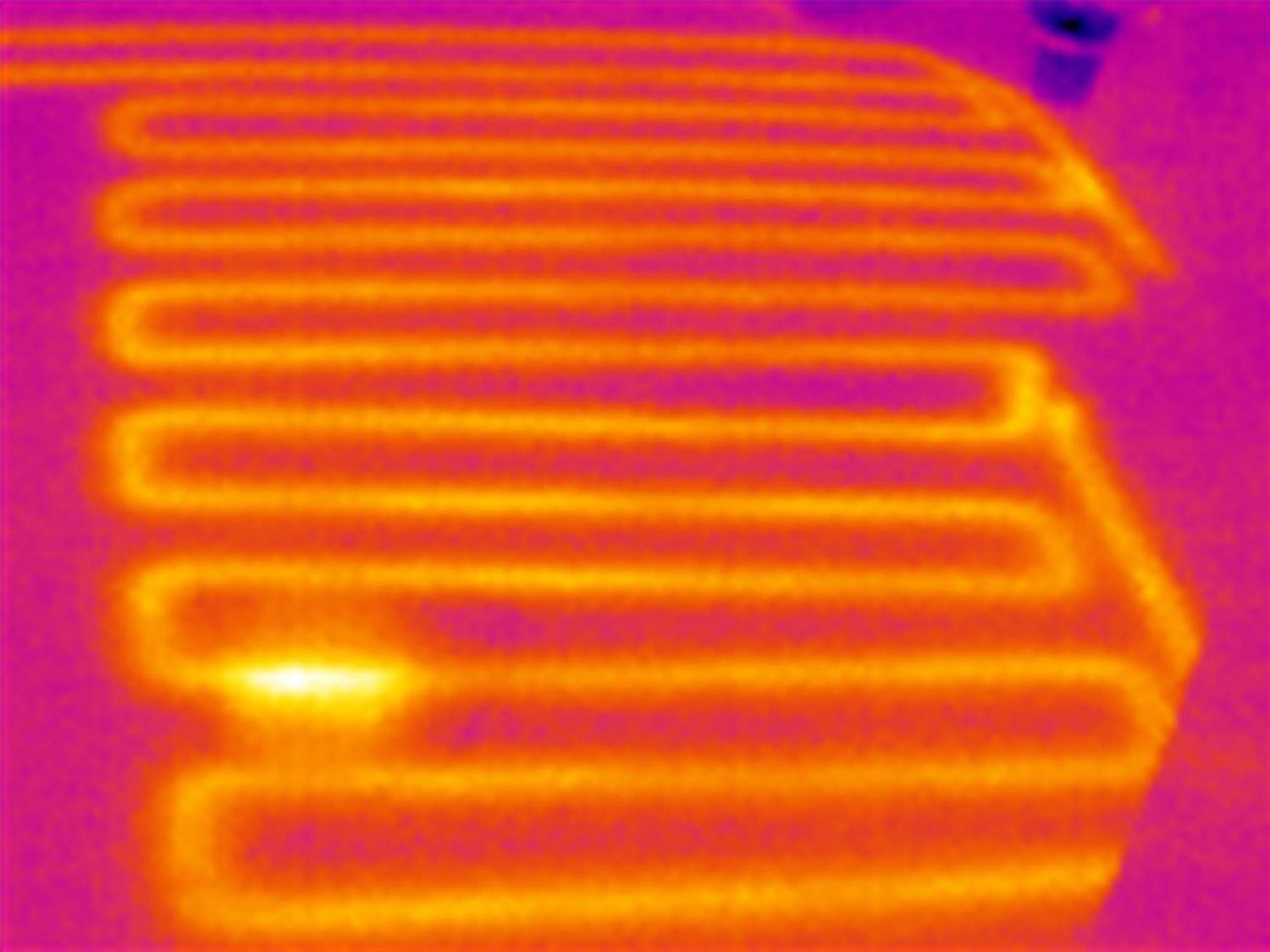

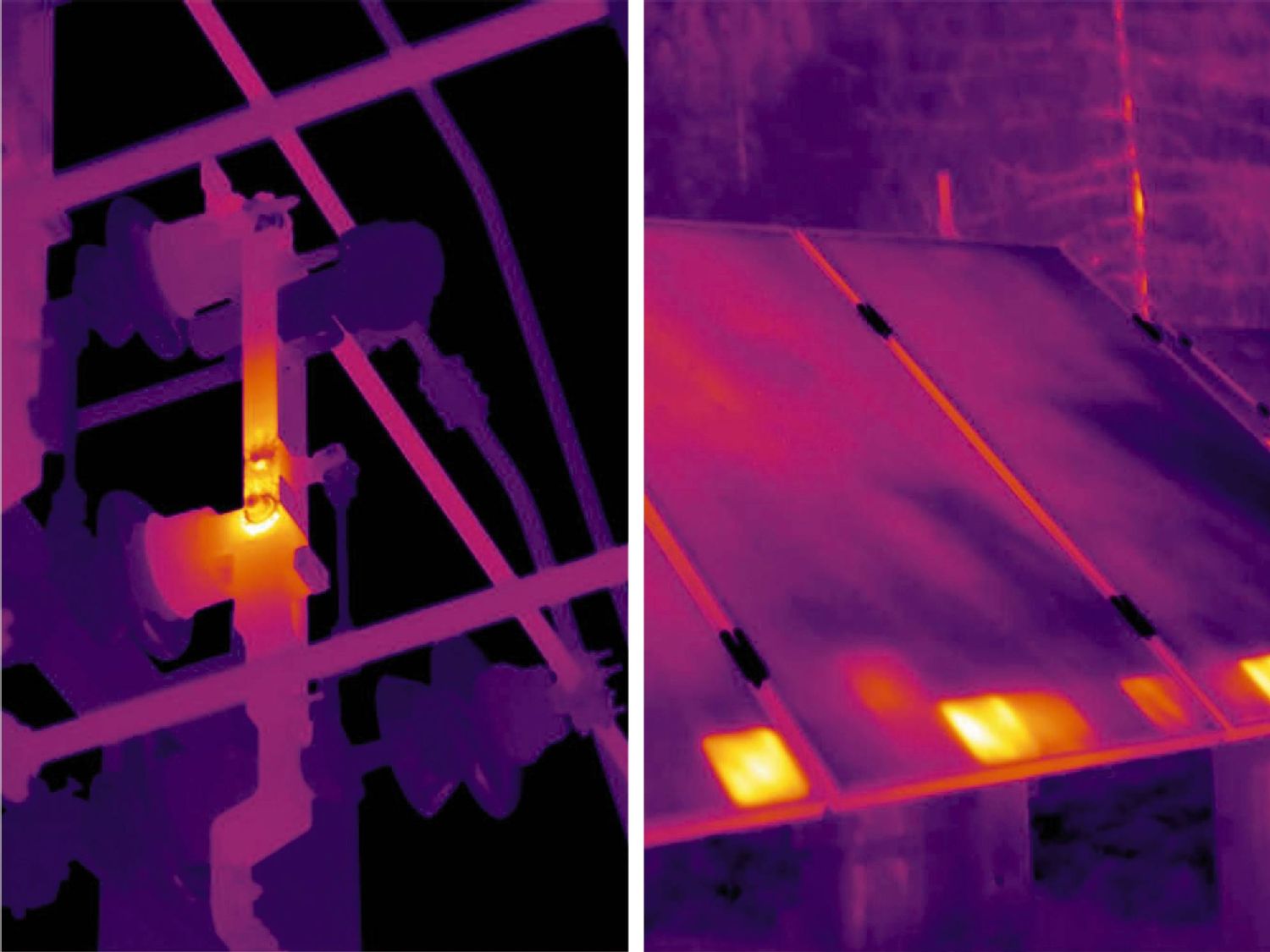

Special features of the thermal imager for industrial thermography

- SiteRecognition technology: for recurrent thermal imaging of similar measurement objects, SiteRecognition technology offers immediate measuring location identification, as well as automatic assignment and archiving of thermal images

- Optional high-temperature measurement up to 1,200°C: with the high-temperature option, the measuring range can be flexibly extended up to 1,200°C

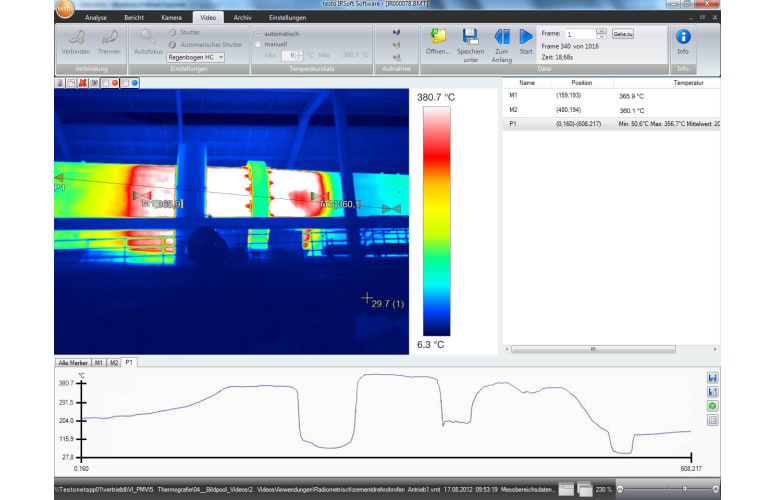

- Process analysis package (optional): the combination of fully radiometric video and sequence capturing in the camera enables wireless measurement and easier handling at the measuring location

Further advantages of the thermal imager

- Lens exchange possible

- Lens protective glass (optional)

- Auto-focus

- Minimum focus distance 10 cm

- Voice recording with headset

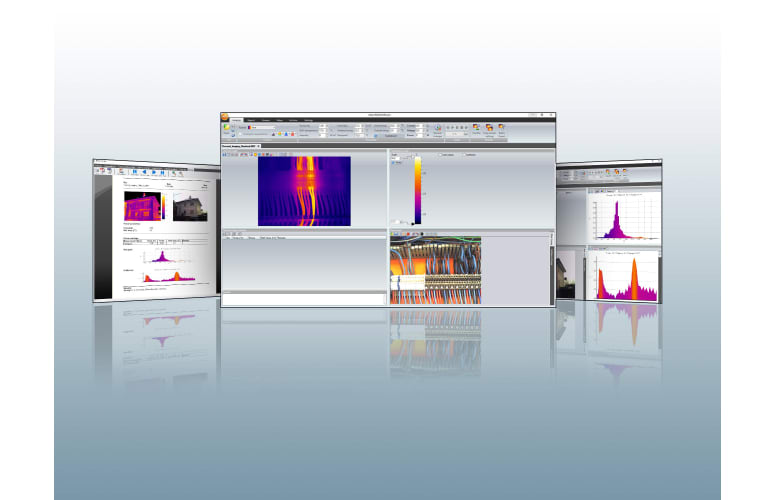

- Analyze thermographic readings directly on the PC with the testo IRSoft professional software

- FeverDetection (optional): use the assistant to check people for high body temperature in public places and in means of transport – for public health protection

Lenses

You are free to choose one from a total of three lenses:30° x 23° standard lens:

- Ideal for inspecting closer measurement objects

- Large field of view

- Ideal for use in applications involving preventive maintenance

- Makes it possible to take outstanding images of measurement objects at medium and longer distances