Preciznost mjerenja, podesivi zaslon mjerenja, mogućnosti paralelnog mjerenja, intuitivan rad, čvrsto kućište, mogućnost povezivanja na testo Smart aplikaciju: Naš analizator dimnih plinova testo 310 II nudi sve što je potrebno instalaterima i tehničarima grijanja za praktičan rad na sustavima grijanja.

Pouzdano ispitivanje sustava grijanja s analizatorom dimnih plinova testo 310 II for beginners

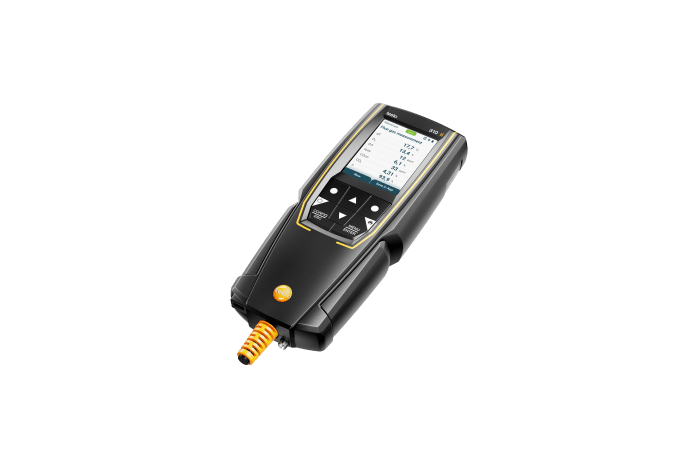

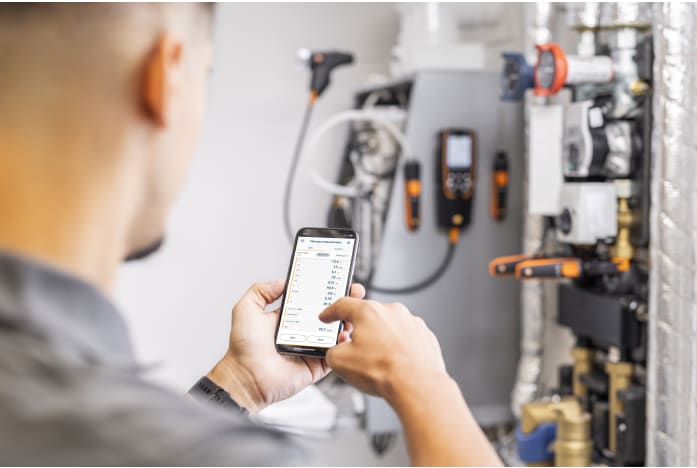

. < P> Kompaktni analizator dimnih plinova nudi, uz jednostavno korisničko sučelje, navigaciju izbornicima s četiri integrirana mjerna izbornika za dimne plinove, propuh, ambijentalni CO i tlak. Svi rezultati mjerenja vidljivi su jednim pogledom na zaslonu i čak se mogu konfigurirati zahvaljujući grafičkom zaslonu visoke rezolucije.Ako je potrebno, ruke vam mogu biti slobodne tijekom mjerenja - jer se analizator dimnih plinova testo 310 II može pričvrstiti na metalne površine, npr. plamenik, pomoću magneta na stražnjoj strani instrumenta. Ali to nije jedina praktična značajka: Testo Smart aplikacija vam omogućuje upravljanje i konfiguriranje vašeg instrumenta putem daljinske funkcije.

Robusna konstrukcija za oštra, prljava okruženja, brzo nuliranje senzora u 30 sekundi, lako zamjenjivi filtar sonde i separator kondenzata koji se može brzo isprazniti čine analizator dimnih plinova optimalnim alatom za mehaniku postrojenja jer je pametno dizajniran.Ako je potrebno, rezultati mjerenja mogu se prenijeti na opcijski dostupan Testo brzi pisač putem Bluetooth® sučelja ili poslati e-poštom i ispisati izravno na licu mjesta.