The testo 350 flue gas analyzer comprises two units

- The testo 350 Control Unit (separate product) with a clear graphic display, allows you to control emissions measurement. Operation is really easy: burner, gas turbine, engine and user-defined applications are available for selection in the menu. The Control Unit enables remote control of the analyzer unit even when there is a spatial separation of the flue gas pipe and the setting location – particularly recommended for emissions measurements on large plants.

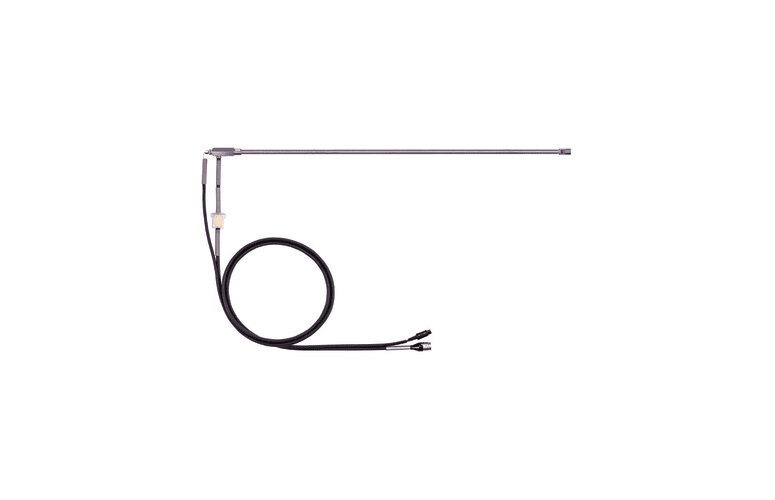

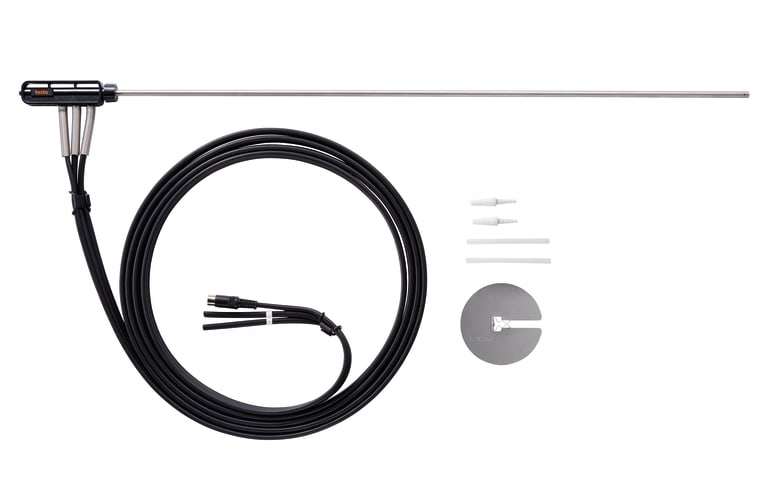

- The testo 350 analyzer unit is just what you need for carrying out emissions measurement, because it contains all the sensor technology and electronics. The testo 350 analyzer unit includes an O2 gas sensor as standard, but at least one additional sensor must be connected for commissioning (can be used with a maximum of 6 sensors). When connecting the optional sensors, you can choose between gas sensors for CO, CO2, NO, NO2, SO2, H2S or CxHy.

The measuring range extension enables unrestricted measurements to be carried out, even when there are high gas concentrations. In order to protect the sensor technology, the measuring range extension (dilution) is automatically activated when there are unexpectedly high gas concentrations. The measuring range of a selected sensor can be extended by a specific factor. The service opening on the underside of the instrument allows fast access to all relevant serviceable and wearing parts, such as pumps and filters, enabling users to clean or replace these. In addition, the testo 350 has numerous instrument diagnosis functions. Instrument notifications are output in cleartext, making them easy to understand. The current status of the flue gas analyzer is constantly displayed.

Using the testo 350 analyzer unit

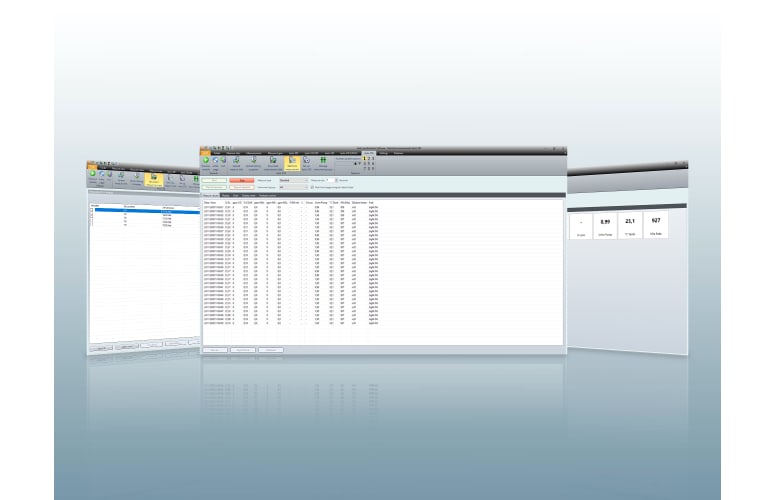

The analyzer unit can be operated with the Control Unit and it can also be used in direct combination with a PC/notebook and the easyEmission software (via USB, Bluetooth® 2.0 or CANCase). After programming, the analyzer unit can carry out measurements and save the results autonomously. It is also possible to display or transmit the measurement data from the analyzer unit to the Control Unit or software.

To send the measurement report straight away, you can also use our free App which turns your Android smartphone or tablet into a display device for the analyzer unit.