Standardized menu structures, which are stored in the flue gas analyzer specific to the country concerned, make for easy operation. Readings are easy to read off on the high-resolution colour display, even when the light is poor. Up to 500 measurement protocols can be saved in the flue gas analyzer.

Quality that you can depend on: the testo 320 flue gas analyzer is TÜV-tested according to EN 50379, Part 1-3 and to 1st German Federal Immission Control Ordinance (BImSchV), Part 1-2 (with integrated, H2-compensated CO cell also Part 3). When you purchase the flue gas analyzer, you get a 2-year warranty (for the instrument, probe, O2/CO sensor).

testo 320 flue gas analysis set: high-efficiency instrument, practical accessories

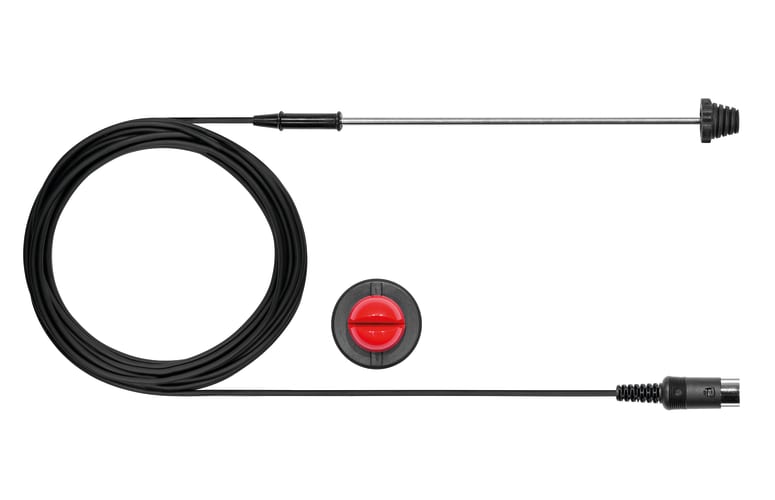

- Ready to start measuring flue gas on heating systems: the testo 320 flue gas analyzer is equipped with two sensors – an O2 and a CO sensor. In this flue gas analysis set, the CO-sensor is H2-compensated. The instrument therefore offers a CO measuring range of up to 8,000 ppm (instead of 4,000 ppm without H2-compensation) and complies with the statutory provisions of the German Federal Immission Control Ordinance (BImSchV). For flue gas measurement, you need a compact or modular flue gas probe. A compact flue gas probe is included in the set. A temperature probe is integrated into the probe. Al relevant flue gas measurement parameters can therefore be calculated: CO2 value, efficiency and flue gas loss. The flue gas analyzer can also be used for flue draught measurements or pressure measurements

- Changing probes is easy: the probes can be changed manually. This means that you can order other optional probes specifically required for your flue gas analysis (e.g. multi-hole probe, dual wall clearance probe, flexible flue gas probe)

- Single-hose connection: just one hand movement is needed to securely connect all channels for the flue gas measurement via the probe coupling (gas paths, draught, temperature probe integrated in the flue gas probe)

- Measurement data management: it is possible to export the measurement protocols in Excel optionally via mini-USB. Further options for managing the measurement data are offered by the PC software easyheat (optional) and the free app TestoDroid for android smartphones and tablets

- Long service life thanks to the long-life Li-ion rechargeable battery

- Built-in magnets enable the flue gas analyzer to be attached to the burner/boiler quickly and easily

- Integrated condensate trap: easy to empty

- Advantage of owning the set: in the set you get the flue gas analyzer with compact flue gas probe, combustion air probe with cone, USB mains unit (with USB cable), testo fast printer (with infrared interface) and instrument case

Fields of application for the testo 320 flue gas analysis set

- Flue gas measurement (combustion air temperature, flue gas temperature, O2, CO and CO2 concentration, flue gas loss, gas/air ratio, efficiency)

- Draught measurement

- Gas flow and gas resting pressure (with optional pressure connection set)

- 4 Pa measurement (with optional fine pressure probe)

- Gas leak detection (with optional probe: CH4 and C3H8)

- Ambient CO and CO2 measurement (with optional probe)

- Differential temperature measurement to determine the spread between flow and return (with optional differential temperature set)