A set of easy-to-follow, self-explanatory, country-specific menus guide you safely through all the measurements. The readings are all presented graphically on a high-resolution, crisp color display for use in all lighting conditions. The user-friendly analyzer also has a memory for up to 500 readings.

Moreover the flue gas analyzer is TÜV-tested according to EN 50379, Parts 1-3 and 1st BImSchV.

The testo 320 flue gas analyzer – facts and features

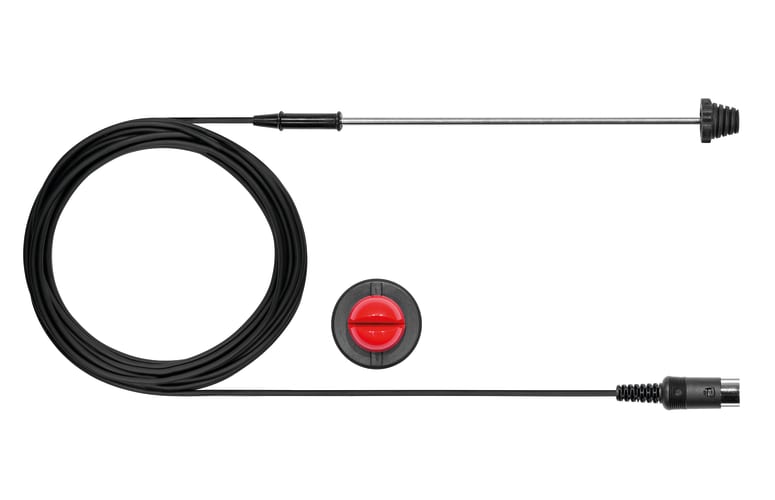

The testo 320 flue analyzer comes with one sensor for O2 and additionally you can order a CO sensor (separate product). The flue gas analyzer then calculates the relevant flue gas values, i.e. CO2 value, efficiency and flue gas loss.There is also wide range of optional sensors for you to choose from. These include multiple-hole, edge crack and flexible flue gas sensors as well as an ultra-fine flue gas pressure sensor which allows you to perform draft and gas pressure measurements parallel to the other measurements.

Areas of application for the testo 320 flue gas analyzer

Six applications. One device:

- flue gas measurements

- flue draft measurements

- gas flow and static gas pressure

- gas leak detection

- CO ambient air measurements

- temperature difference measurements