Intuitive operation

The touchscreen operation and large colour display make configuration, control and documentation much easier. This makes operation of the manifold faster and more intuitive. When working with gloves, the manifold can be operated using keys in addition to the touchscreen.

Ready for any refrigerant

For maximum safety, the manifold is also compatible with Class A3 and A2L flammable refrigerants. With a wide selection of 96+ refrigerants, all common refrigerants are stored in the manifold. Frequently used refrigerants can be marked as favourites for quick retrieval.

Accurate measurement results on an easy-to-read display

High accuracy of 0.25 full scale and new, clear measurement graphs make system analysis easy and reliable.

Data logging

Readings can be recorded for up to 30 minutes and displayed as trend curves. This allows anomalies to be quickly identified. Optionally, the manifold can be extended to a logging capacity of 72 hours.

Easy data management

The readings can be directly exported and sent as a measurement report via the testo Smart App, so that the documentation can be completed on site in just a few clicks.

Ready for any application with full connectivity

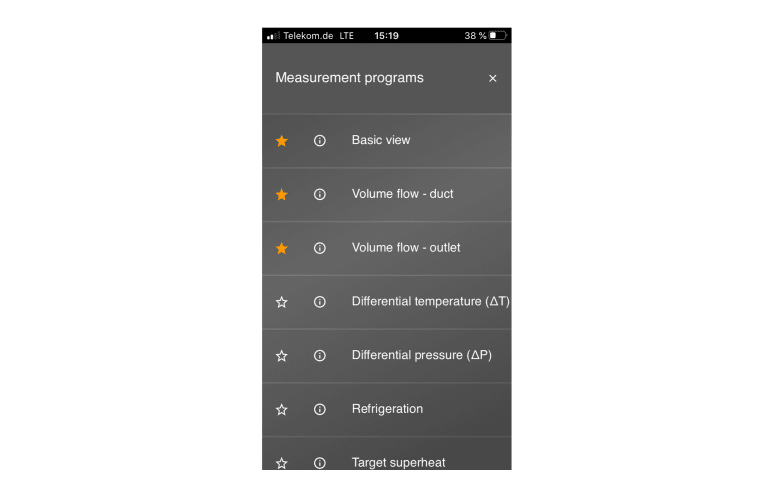

Superheating and subcooling, tightness testing, Delta T, evacuation or filling - thanks to a wide range of measurement programs and connectivity to the entire refrigeration portfolio, all applications can be controlled and documented via the manifold.

Reliable and robust

The IP54 protection class ensures a high level of robustness and durability.

Always up to date

Thanks to free updates (OTA), the manifold can be regularly updated. This allows, for example, new refrigerants to be added and connectivity to new products to be enabled.