The flue gas measurement for a heating system helps to establish the pollutants released with the flue gas (e.g. carbon monoxide CO) and the heating energy lost with the warm flue gas. In some countries, flue gas measurement is a legal requirement. It primarily has two objectives:

1. Ensuring the atmosphere is contaminated as little as possible by pollutants; and

2. energy is used as efficiently as possible.

Stipulated pollutant quantities per flue gas volume and energy losses must never be exceeded.

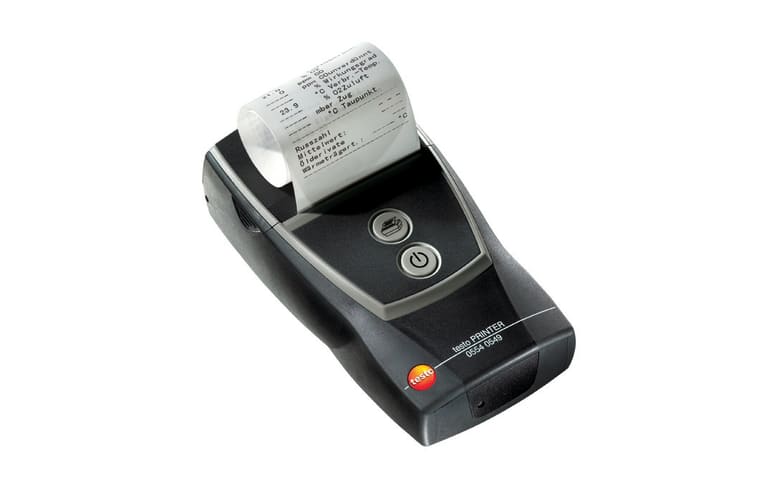

Measurement in terms of results required by law takes place during standard operation (every performance primarily using the appliance). Using a Lambda probe (single hole or multi-hole probe), the measurement is taken at the centre of flow in the connecting pipe (in the centre of the pipe cross-section, not at the edge) between the boiler and chimney/flue. The measured values are recorded by the flue gas analyzer and can be logged either for print out or transfer to a PC at a later stage.

Measurement is taken by the installer at commissioning, and if necessary four weeks later by the flue gas inspector/chimney sweep, and then at regular intervals by the authorised service engineer.