- Home

- testo 108

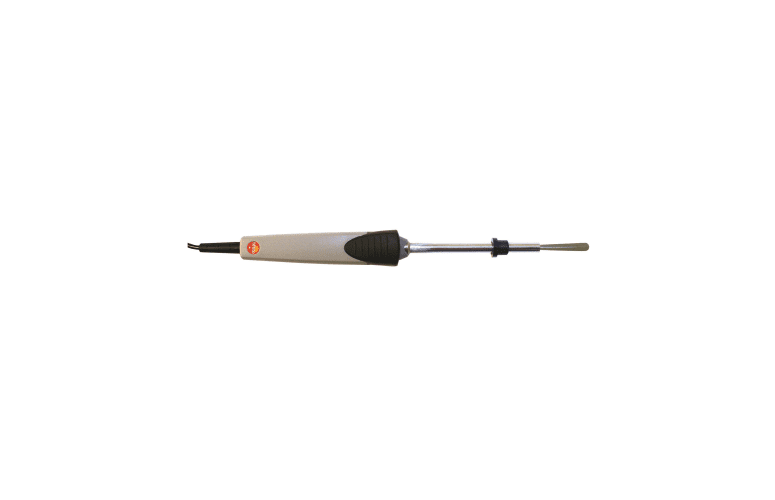

testo 108 - Digital food thermometer

0563 1080testo 108 - Digital food thermometer

0563 1080The testo 108 digital food thermometer ticks the box on both counts. It is fast. It is reliable. And there are added benefits too…

- Ideal for all sectors of the food industry. From buying to transport, from storage to production and control

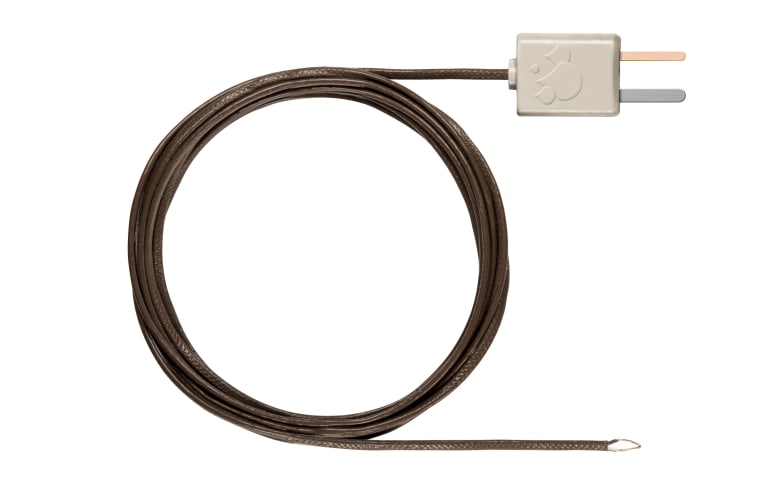

- Protective softcase and type T thermocouple probe sensor included

- Super fast measurements, super reliable readings

- Easy to use with self-explanatory keys and large, easy-to-read display. No need for lengthy instructions

- Hygienic: softcase and food thermometer/sensor can be easily cleaned under running water

- HACCP and EN 13485 compliant

Areas of application for the testo 108 digital food thermometer

Ideal for use during transport or storage of food, in restaurants, canteen kitchens or system catering: the testo 108 waterproof food thermometer enables you to integrate your temperature measurements effortlessly into your daily routine while making sure that the quality of your food complies with HACCP regulations.

Temperature - TC Type K (NiCr-Ni)

| Measuring range | -50 to +300 °C |

|---|---|

| Accuracy | ±0.5 °C ±0.5 % of mv (-50 to -30 °C) ±0.5 °C ±0.5 % of mv (+70 to +300 °C) ±0.5 °C (-30 to +70 °C) |

| Resolution | 0.1 °C |

Temperature - TC Type T (Cu-CuNi)

| Measuring range | -50 to +300 °C |

|---|---|

| Accuracy | ±0.5 °C ±0.5 % of mv (-50 to -30 °C) ±0.5 °C ±0.5 % of mv (+70 to +300 °C) ±0.5 °C (-30 to +70 °C) |

| Resolution | 0.1 °C |

| Reaction time | 10 s (Measured in moving liquid) |

General technical data

| Weight | 210 g (incl.battery and Softcase) 154 g (incl. battery, without softcase) |

|---|---|

| Dimensions | 140 x 60 x 24 mm |

| Operating temperature | -20 to +60 °C |

| Product-/housing material | ABS / ABS-PC fibre glass 10% |

| Protection class | IP67 (with connected Testo probe included in delivery) |

| Product colour | white |

| Measuring rate | 0.5 s |

| EU-/EG-guidelines | 2004/108/EG |

| Standards | EN 13485 |

| Battery life | 2500 h (typical, at 23 °C) |

| Battery type | 3 AAA micro batteries |

| Display function | with status line |

| Display size | one-line |

| Display type | LCD |

| Storage temperature | -30 to +70 °C |

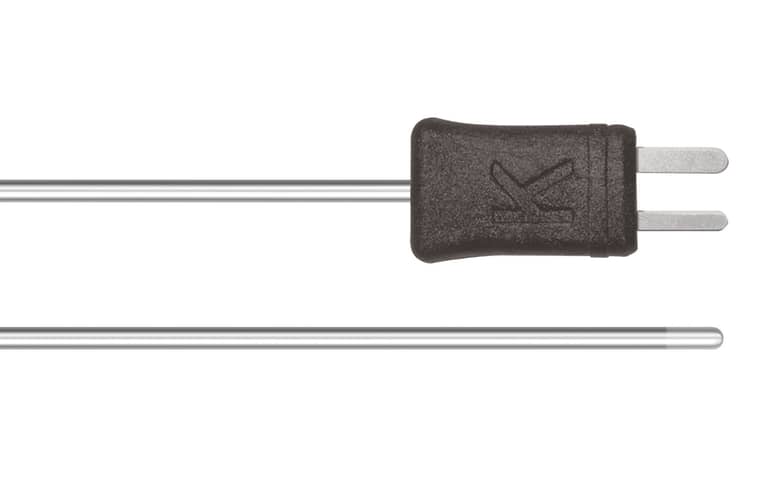

Air probes

0602 1793

0603 1793

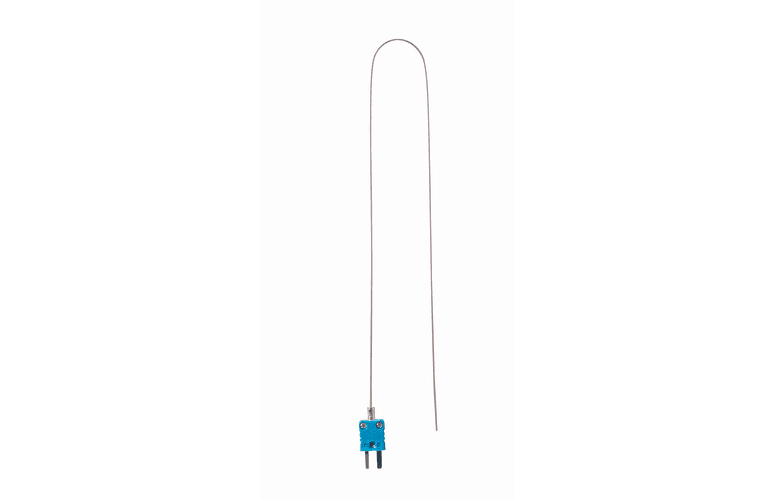

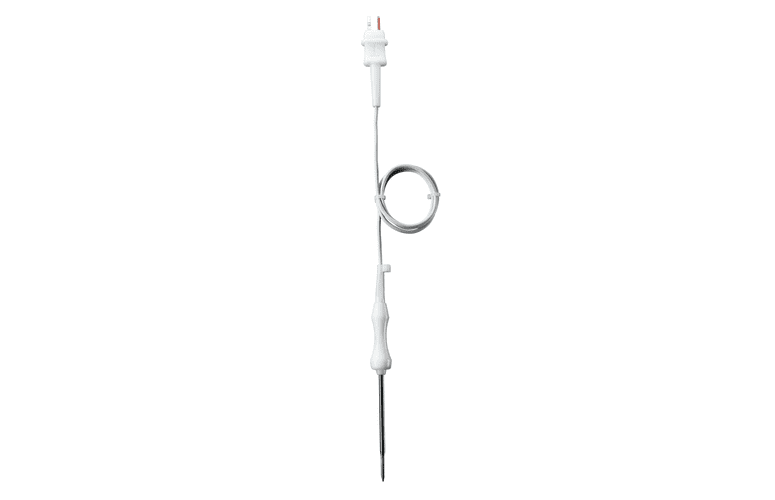

Immersion/penetration probe for food measurements

0602 2292

0603 0646

0603 1293

0603 2192

0603 2492

0603 2693

0603 3292

0603 3392

0628 0023

0628 0027

0628 0030

0628 1292

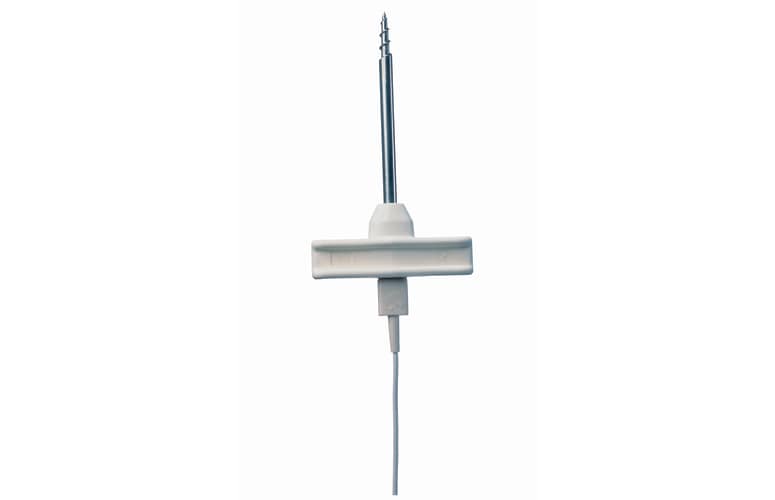

Surface probes

0602 0193

0602 0393

0602 0693

0602 0993

0602 1993

0602 2394

0602 4592

0602 4692

0602 4792

0602 4892

0603 1993

0628 0020

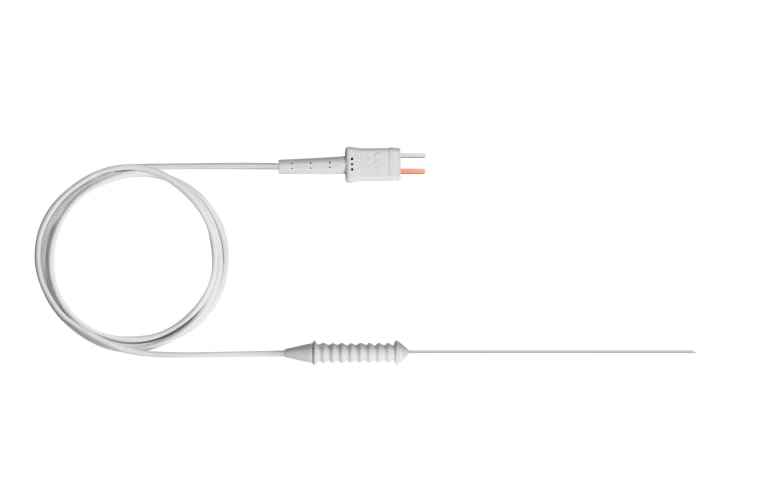

immersion/ penetration probes

0602 0593

0602 0644

0602 1080

0602 1293

0602 2693

0602 5693

0602 5792

Accessories

0554 0004

0554 0592

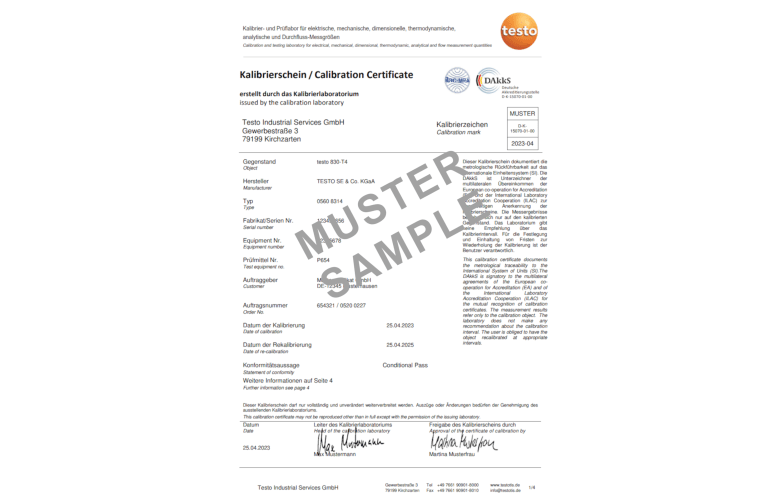

Certificates

0520 0001

0520 0061

0520 0062

0520 0063

0520 0071

0520 0072

0520 0073

0520 0181

0520 0211

Monitoring product temperatures

In the area of food production and meal distribution, the correct heating up and temperature of the food play a crucial role in terms of controlling germ/bacteria generation and reproduction on the food dishes, as well as controlling the consumption temperature.

- Measurement directly during the production process/or after food preparation

- Ensuring the necessary temperature: regarding germs/bacteria, but also quality specifications “defined internally”; (e.g. when heating chocolate it must not be heated too much/too quickly)

Advantages of testo 108:

- Ease of operation and use

- Waterproof instrument and probe (IP67)

- Conforms to HACCP and EN 13485

- Can be used universally

Temperature check during storage

The temperature check measuring task for storage is to ensure that the temperature of goods complies with (statutory) regulations and that the goods can be “safely” accepted and used for consumption (maintaining the cooling chain).

For contact measurements, a measurement is normally taken from between the products (carton packaging, frozen foods), and a core temperature is measured. In cases of doubt, a core measurement is of interest. Our frozen food probe 0603 3292 is inserted into the frozen food for this purpose.

This refers to both storage in cold storage warehouses/refrigerated transport means and refrigeration for sales counters (e.g. in supermarkets).

Advantages of testo 108:

- Ease of operation and use

- Waterproof instrument and probe (IP67)

- Conforms to HACCP and EN 13485

- Can be used universally

Temperature checks in incoming goods

The temperature check measuring task in incoming goods is to ensure that the temperature of supplied goods complies with (statutory) regulations and that the goods can be “safely” accepted and used for further processing.

Both the temperature between the products and the core temperature of foods can be measured.

In most cases, data is entered on a form and documented for subsequent traceability. In addition to the measured value, the date, time and user are noted.

If the temperature of the supplied goods complies with statutory regulations, these can be accepted and processed.

Advantages of testo 108:

- Ease of operation and use

- Waterproof instrument and probe (IP67)

- Conforms to HACCP and EN 13485

- Can be used universally

- Data sheet testo 108(pdf, 389.54 kB)

- HACCP Certificate Equipment Temperature Monitoring(pdf, 202.68 kB)

- Instruction manual testo 108(pdf, 4.81 MB)