- Home

- testo 890 kit

testo 890 kit - Thermal imager (640 x 480 pixels, focus manual/auto, laser, 3 lenses selectable)

0563 0890 X3

testo 890 kit - Thermal imager (640 x 480 pixels, focus manual/auto, laser, 3 lenses selectable)

0563 0890 X3Exceptional Image Resolution – 640 × 480 pixels, upgradable to 1280 × 960 pixels with SuperResolution technology for exceptional thermal imaging precision.

Complete Lens Set for Maximum Flexibility – Includes all three lenses: 42° standard, 25°, and 15° telephoto, ensuring adaptability for any application.

Innovative Features for Versatile Use – Integrated digital camera, SiteRecognition, panorama assistant, humidity calculation, and optional high-temperature measurement up to 1,200°C.

Ergonomic & User-Friendly Design – Camcorder-style build with a rotatable display, auto-focus, and one-hand operation for easy handling.

Advanced Thermal Sensitivity – Detect even the smallest temperature differences with a sensitivity of < 40 mK.

The testo 890 Kit (X3) is a premium thermal imaging solution designed for professionals in industrial maintenance, building diagnostics, and research & development. Equipped with a high-resolution 640 × 480 pixel sensor (expandable to 1280 × 960 pixels), this kit includes all three lenses—standard (42°), 25°, and 15° telephoto—offering the ultimate flexibility for close-range, mid-range, and long-distance thermal inspections. The ergonomic camcorder-style design, auto-focus, and advanced analysis features make it the perfect tool for high-precision thermographic applications.

The testo 890 Kit (X3) is the most versatile thermal imaging camera in the testo 890 series, providing users with all three lens options for unmatched flexibility in various applications. This kit includes all three available lenses: the 42° standard lens for wide-field imaging, the 25° lens for balanced mid-range analysis, and the 15° telephoto lens for detailed long-distance thermal inspections. This makes the camera ideal for a wide range of applications, from energy audits and electrical inspections to high-temperature industrial monitoring and scientific research. The ability to switch between lenses allows users to capture thermal images with the ideal level of detail and field of view for any given scenario.

The testo 890 Kit (X3) is packed with advanced thermography features that streamline inspections and enhance analysis. The Panorama Image Assistant enables users to stitch multiple thermal images together, providing a comprehensive view of large structures such as entire building facades. SiteRecognition Technology simplifies repeat inspections by automatically identifying and archiving measurement locations. For high-temperature applications, the optional high-temperature mode extends the measuring range up to 1,200°C, making it an essential tool for industries such as steel production, power plants, and manufacturing. Additionally, the mould risk detection mode calculates dewpoint levels to highlight areas susceptible to mould growth, improving building diagnostics and energy consultancy.

Designed with ergonomics and ease of use in mind, the testo 890 Kit (X3) features a camcorder-style design with a rotatable, fold-out display, making it comfortable to use from various angles. The auto-focus function ensures sharp thermal images while allowing for one-handed operation, enhancing efficiency in the field. The integrated digital camera with power LEDs captures real images alongside thermal ones, providing additional reference for documentation. With a minimum focus distance of just 10 cm, this camera is also perfect for detailed close-up inspections, such as circuit board analysis and electronic component testing.

Included in the testo 890 Kit (X3) is a full suite of accessories, ensuring a complete and professional thermographic solution. This includes a robust transport case, a memory card for image storage, and Testo IRSoft professional software for detailed image analysis and reporting. A headset is also included, enabling users to record voice annotations directly onto thermal images for more efficient documentation.

- testo 890 thermal imager with SuperResolution

- 3 x lenses (standard, 25° and telephoto lens)

- Transport case

- Pro software IRSoft (free download)

- Carrying strap for the thermal imager

- SD memory card

- USB cable for data transfer to the PC

- Lens cleaning cloth

- Mains unit

- Li-ion rechargeable battery

- Headset for voice recording

- Lens case

- Lens protective glass

- Spare rechargeable battery

- Fast battery charger

Standards

| EU-/EG-guidelines | 2004/108/EG |

|---|---|

Infrared image output

| Field of view | 42° x 32° (Standard lens), 25° x 19° (25° lens), 15° x 11° (Telephoto lens), 6.6° x 5° (Supertele) |

|---|---|

| Focus | auto / manual |

| Minimum focus distance | 0.1 m (Standard lens), 0.2 m (25° lens), 0.5 m (Telephoto lens), 2 m (Supertele) |

| Geometric resolution (IFOV) | 1.13 mrad (Standard lens), 0.68 mrad (25° lens), 0.42 (Telephoto lens), 0.18 (Supertele) |

| Image refresh rate | 33 Hz |

| Infrared resolution | 640 x 480 pixels |

| SuperResolution (IFOV) | 0.71 mrad (Standard lens), 0.43 mrad (25° lens), 0.26 mrad (Telephoto lens), 0.11 mrad (Supertele) |

| SuperResolution (Pixel) | 1280 x 960 pixels |

| Thermal sensitivity | ˂ 40 mK at +30 °C |

| Spectral range | 7.5 to 14 µm |

| *inside the EU, outside 9 Hz | |

Image output visual

| Minimum focus distance | 0.5 m |

|---|---|

| Image size | 3.1 MP |

Accessories

Accessories

Lens protection glass - for protection of the lens against dust and scratching

:

0554 0289

0554 0289

£ 514.00 £ 616.80

1

Accessories

Additional battery. Additional lithium-ion rechargeable battery for extending the operating time.

:

0554 8852

0554 8852

£ 112.00 £ 134.40

1

Accessories

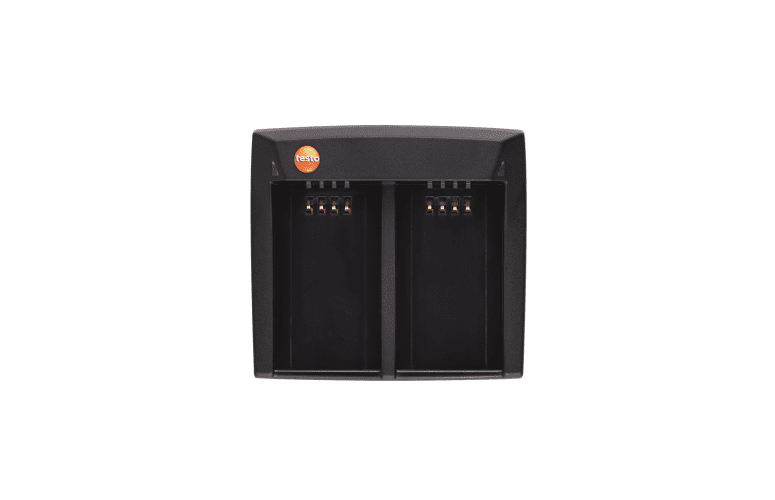

Fast charging station - desktop fast charging station for two rechargeable batteries

:

0554 8851

0554 8851

£ 259.00 £ 310.80

1

Overview of applications

Preventive maintenance

Detecting structural defects and ensuring construction quality

Professional energy consultation

Present and analyze building shells in an image

Preventing mould formation

Easy checking of heating systems and installations

Localize pipe ruptures

Locating leaks in flat roofs

More reliability in quality assurance and production monitoring

Safe high-temperature measurement

Research and development

Energy supply (production and distribution)

Detecting structural defects and ensuring construction quality

Professional energy consultation

Present and analyze building shells in an image

Preventing mould formation

Easy checking of heating systems and installations

Localize pipe ruptures

Locating leaks in flat roofs

More reliability in quality assurance and production monitoring

Safe high-temperature measurement

Research and development

Energy supply (production and distribution)

Preventive maintenance

Ideal for the early identification of imminent malfunctions or defects on plants and machines: Reliably record temperature increases with a thermal imager.

- Fast detection of critical thermal status (so-called HotSpots) during continuing operation

- Avoid expensive damage, downtimes and fire risks on plants and machines

- Test switching cabinets, electrical conditions, photovoltaic plants

- Evaluate heat status in low, medium and high voltage plants

- Identify wear on machines

- Test motors, bearings, shafts

Detecting structural defects and ensuring construction quality

- Detect potential building defects, prove quality and the implementation of construction measures without contact – with the help of thermal images

- Test air-tightness of windows and doors

- Locate insulation errors and cold bridges in a building shell

- Detect and visualize mould-risk areas

Professional energy consultation

- Analyze building shells, evaluate energy efficiency, identify energy-saving potential with a thermal imager from Testo

- Easy recording and documentation of energy loss from buildings

- Prove faulty insulation and cold bridges without contact, and visualize them in an infrared image

- Localize untight spots in new buildings quickly and easily in combination with Blower Door

Present and analyze building shells in an image

- Detailed thermograohy of large buildings

- Visualize thermal irregularities in a building shell – in a thermal image: The panorama assistant stitches severla recordings together to one overall image

Preventing mould formation

- Localize mould-risk areas quickly and easily: These areas are presented in red in the imager display when the imager is in humidity mode

Easy checking of heating systems and installations

- test heating and air conditioning/ventilation systems: Use a thermal imager to identify irregularities in the temperature distribution quickly and easily

- Localization of the course of heating loops in underfloor heating systems

- Testo radiators for silting

- Measure flow and return temperatures

Localize pipe ruptures

- Reliably determine pipe ruptures with the help of a thermal imager – without unnecessarily opening walls and floors

- Precise localization of leakages in underfloor heating and other inaccessible pipe systems

Locating leaks in flat roofs

- Detection of damp in roofs: Based on temperature differences (such as occur mainly in flat roofs), thermal imagers show areas on the roof with sealed-in moisture or damaged insulation

More reliability in quality assurance and production monitoring

- A Testo thermal imager supports in process control and product quality asurance

- Identify foreign bodies in production processes and anomalies in the heat distribution of components quickly and without contact

- Fast and easy monitoring of filling level in closed liquid tanks

Safe high-temperature measurement

- Measure high temperatures safely from a distance: Some of the thermal imager models from Testo even measure up to 1200 °C with the high-temperature option

- Ideal for use in industrial maintenance

- Identify wear, insulation damage and coking in furnaces and smelters

- Thermography of large furnaces and machines on one thermal image – e.g. rotary kilns in cement production

Research and development

- Identify thermal anomalies and monitor cooling and heating processes in real time

- Precisely visualize critical temperatures on circuit boards: Thanks to the finest geometric resolution of the high-quality Testo thermal imagers

- Analyze heat occurrence and conduction in circuit boards, and optimize development processes: The process analysis package offers practical features such as video recording and image sequence storage for easy analysis of thermal processes

Energy supply (production and distribution)

- Thermographic testing of energy distribution plants: With thermal imagers, you can test thermal warming from a safe distance without contact, e.g. on high-voltage lines and in transformer stations

- Non-contact testing of photovoltaic plants: Using solar thermography, module defects and installation faults can be reliably detected

- Data sheet testo 890(pdf, 1.46 MB)

- Product brochure testo 890(pdf, 5.47 MB)

- EU declaration of conformity testo 890(pdf, 34.35 kB)

- Instruction manual testo 890(pdf, 1.74 MB)

- Testo thermal imagers Instrument firmware (testo 885, 890)(v1.88, 21.78 MB)In order to be able to use the PC software optimally, the instrument should also be updated with the latest version of the instrument firmware. Please observe the instruction for the Instruction Firmware update. Please note: For the Firmware upgrade the current IRSoft is essential.

- LabVIEW interface description (testo 890, 885)(pdf, 78.9 kB)