Reliable testing of heating systems with the flue gas analyzer testo 310 II for beginners

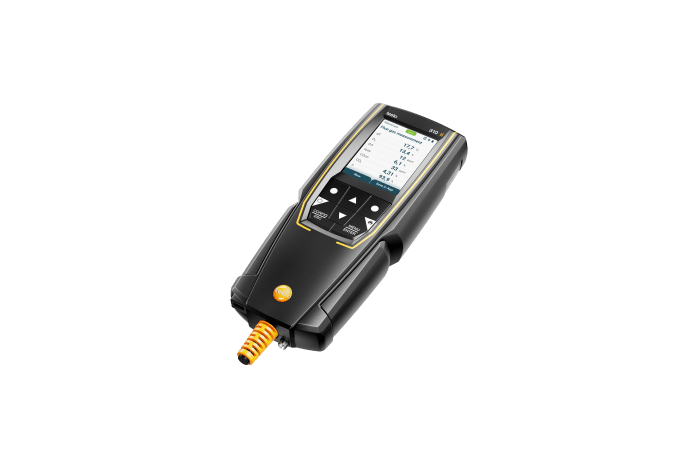

The compact flue gas analyzer offers, in addition to the simple user interface, menu navigation with four integrated measurement menus for flue gas, draught, ambient CO and pressure. All measurement results are visible at a glance in the display and can even be configured, thanks to the high-resolution graphic display.

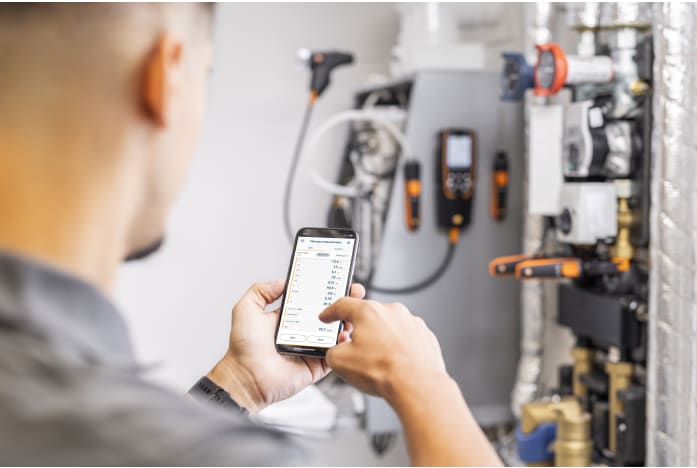

If needed, you keep your hands are free during the measurement - because the flue gas analyzer testo 310 II can be fixed to metal surfaces, e.g. the burner, using the magnets on the back of the instrument. But this is not the only practical feature: The testo Smart App allows you to operate and configure your instrument via the remote function.

The robust design for harsh, dirty environments, the fast sensor zeroing in 30 seconds, the easily replaceable probe filter and the condensate trap that can be emptied quickly make the flue gas analyzer the optimal tool for plant mechanics because it is cleverly designed.

If required, the measurement results can be transferred to the optionally available Testo quick printer via Bluetooth® interface or sent by e-mail and printed out directly on site.