- Home

- testo 635-2

testo 635-2 - Thermohygrometer

0563 6352

testo 635-2 - Thermohygrometer

0563 6352With two plug-in sensor ports and the ability to connect up to three additional wireless sensors, the testo 635-2 provides flexible and comprehensive data collection. Users can also benefit from the ability to calculate dew point differences, which helps analyse moisture levels on surfaces such as ceilings and walls, crucial for preventing mold and structural damage.

Equipped with a super-size memory, the device can store up to 10,000 readings, making it ideal for long-term monitoring. The included USB cable and PC software enable easy data transfer and archiving, while the testo fast printer (optional) allows for instant printouts directly on-site.

Designed for convenience, the testo 635-2 features a backlit display for easy readability in poor lighting conditions, an intuitive menu navigation system, and a robust protective casing to withstand demanding environments. Whether in climate control, building diagnostics, or industrial quality assurance, the testo 635-2 delivers reliable, high-precision measurements with user-friendly operation.

testo 635-2 - Thermohygrometer, PC software and USB-cable incl. battery and calibration protocol

Temperature - NTC

| Measuring range | -40 to +150 °C |

|---|---|

| Accuracy | ±0.4 °C (-40 to -25.1 °C) ±0.4 °C (+75 to +99.9 °C) ±0.5 % of mv (Remaining Range) ±0.2 °C (-25 to +74.9 °C) |

| Resolution | 0.1 °C |

Temperature - TC Type K (NiCr-Ni)

| Measuring range | -200 to +1370 °C |

|---|---|

| Accuracy | ±(0.2 °C + 0.5 % of mv) (Remaining Range) ±0.3 °C (-60 to +60 °C) |

| Resolution | 0.1 °C |

Humidity - Capacitive

| Measuring range | 0 to +100 %RH |

|---|---|

| Accuracy | See probe data |

| Resolution | 0.1 %RH |

Air probes

0602 1793

Humidity probes

0636 2135

0636 2161

0636 6160

Radio handles and probe head

0554 0189

0602 0394

0636 9736

Surface probes

0602 0092

0602 0193

0602 0393

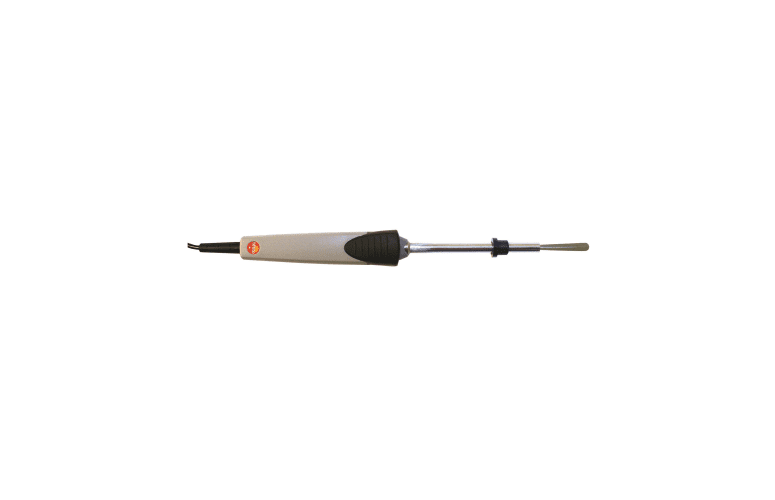

Thermocouples

0602 0644

0602 0645

0602 0646

immersion/ penetration probes

0602 0593

0602 1293

0602 2693

Cases

0516 1435

0516 1035

Further accessories measuring instrument/probes

0554 0660

Printer and accessories

0554 0447

0554 0610

0554 0568

Radio handles and probe head for surface measurement

0554 0188

Radio handles, seperate county variant

0554 0189

Localising mould

Damp ceilings and walls may be a result of structural damage. In most cases, however, it is a sign of improper ventilation. Once the mould appears inside a house, the tenant assumes that moisture has come in from outside. Numerous disputes have erupted because of the issue of who is liable for the mould damage. However, it is difficult to find out who or what has caused the mould: the tenant or faulty structural design?

Testo 635-2 is ideal for measuring moisture in ceilings and walls. Using the optional attachment temperature/moisture probe and optional surface temperature probe, the testo 635 automatically calculates the dew point distance. It provides initial information about whether mould is being caused by condensation, or from moisture ingress due to structural damage or faulty insulation.

The supplied PC software can be used to document and analyse the measurement data.

Measuring material moisture

Monitoring the moisture in construction materials and different timber is an important part of everyday work in the most diverse areas. For many users, measuring the material moisture as quickly and as non-destructively as possible is crucial.

Whether it is used to assess the screed drying process, further processing, or the combustibility of wood, our testo 635-2 hygrometer can be used to examine the moisture content in many different construction materials and types of wood.

Monitoring drying processes

Whether freshly laid screed, or monitored drying of moisture damage, timely determination of the required moisture level will save time and therefore money.

Screeds are laid in the in interior works stage, generally after plastering. The flooring and painting and decorating then follow. The drying behaviour is therefore a significant factor in the works schedule, primarily because the laying of flooring depends on this.

The moisture measurement establishes readiness for flooring; liability for the flooring is thus transferred to the respective trade installing the flooring. An important part of this work is therefore documentation and assurance in the testing for readiness for flooring.

What is the extent of moisture damage and what consequences can be expected in terms of time and costs? These questions have to be answered in order to decide which auxiliary tools and materials are to be used to speed up the drying process.

The t 635-2 and attachment scatter field probe can be used to measure the moisture in the construction material.

Using a thin moisture probe combined with the testo 635-2 the moisture of construction materials can be determined by means of an equilibrium moisture measurement. To do this, the probe has to be inserted in a borehole in the material being measured and sealed. The relevant material characteristic can be manually entered into the device or via software. After several hours, equilibrium with the material has taken place and the testo 635-2 displays the material moisture.

Monitoring production and storage conditions

Our temperature/humidity measuring instruments are used around the world in production, storage and server rooms, museums, archives, cold storage warehouses, containers and sales counters.

Manufacturers, carriers, or dealers of sensitive products must ensure that specified temperature or humidity values are observed during production and storage. The testo 635 offers the option of performing spot measurements in relevant places.

The temperature/humidity measuring instrument testo 635-2 offers the user a wide range of humidity/moisture probes. It provides the option of measuring humidity, material moisture and U-value (for the thermal assessment of structural components). In addition to the standard probes, up to three radio probes can be connected to the device in parallel. Measurement results can be analysed, stored and documented using the supplied PC software.

U-value measurement in old buildings

When redeveloping or renovating old buildings, it is crucial to be able to determine quickly if heat is being lost through the windows and walls. Only then can energy costs be reduced and redevelopment measures carried out efficiently.

When assessing thermal transmission, e.g. in old buildings in need of renovation, the U-value is one of the most important values. It enables thermal assessment and monitoring of the installed material.

3 temperature values are required for calculating the U-value:

- Outside temperature

- Surface temperature of the internal wall

- Indoor air temperature

A radio probe is needed to determine the U-value; this is placed in position outside. It transmits the readings to the measuring instrument inside. To measure the surface temperature the three wires of the U-value probe are attached to the wall with plasticine. The air temperature is recorded by a sensor located on the probe plug. The measuring instrument testo 635-2 automatically calculates the U-value from the three values and shows this on the display. The advantage: there is no need for manual calculation; the result is quick and accurate.

Measuring wood moisture quickly and non-destructively

The testo 635-2 uses the optional attachment scatter field probe (item no.: 0636 6160) to quickly and non-destructively examine the material moisture in timber. Characteristic curves are available for measuring wood moisture in soft and hard woods, and chipboard. These characteristic curves were developed in cooperation with the LPI institute.

The measurement results are calculated up to a depth of 5 cm and can be recorded at the touch of a button. The readings are displayed in percent by weight in comparison to the dry mass of the material.

Measurement data can be stored and documented using PC software.

- Data sheet ComSoft Basic/ Professional/ CFR(pdf, 597.65 kB)

- Product brochure testo 635(pdf, 811.18 kB)

- UK Declaration of Conformity testo 635-2(pdf, 61.83 kB)

- Short manual testo 635-1/-2(pdf, 46.97 kB)

- Instruction manual testo 635-1/-2(pdf, 823.74 kB)

- testo usb driver - Instruction manual(pdf, 676.7 kB)

- testo usb driver - for various measuring instruments(v2.9.1, 2.02 MB)USB driver for the following devices with USB port: * USB Interface testo 174 / 177 - T + H * testo 300 / 320 / 330 / 330i / 335 / 340 / 350 * testo 435 * testo 556 / 560 / 570 / 580 * testo 635 * testo 735 * testo 845