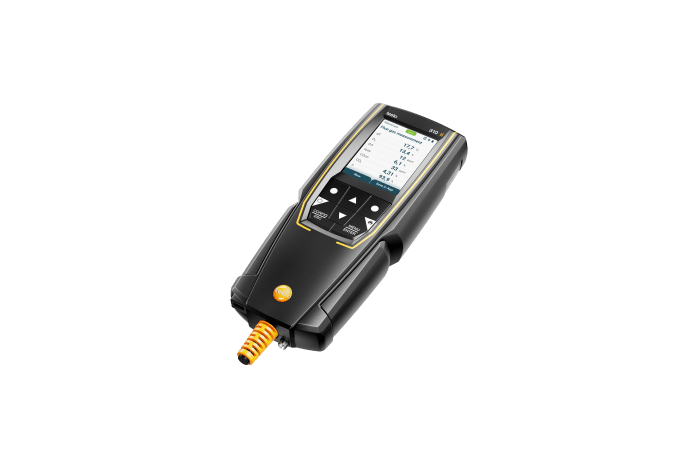

Testo 310 II ima dve merilni celici za O2 in CO ter temperaturni senzor, vgrajen v sondo za dimne pline. Plinski senzorji merijo natančno vsebnost kisika in ogljikovega monoksida ter temperaturo dimnih plinov in okolice. Iz teh podatkov se izračunajo vsi pomembni merilni parametri, kot so vrednost CO2, stopnja učinkovitosti in izgube dimnih plinov. Poleg tega ima merilni instrument svoje prednosti v natančnosti merjenja, konfigurabilnem prikazu meritev, možnosti vzporednih meritev, intuitivnem delovanju, trpežnem ohišju in možnosti povezave z aplikacijo testo Smart App: Naš analizator dimnih plinov testo 310 II ponuja vse, kar potrebujejo moterji in tehniki za praktično delo na ogrevalnih sistemih.

Zanesljivo testiranje ogrevalnih sistemov z analizatorjem dimnih plinov testo 310 II za začetnike

Kompaktni analizator dimnih plinov ponuja, poleg preprostega uporabniškega vmesnika, tudi menijsko navigacijo z štirimi integriranimi merilnimi meniji za dimne pline, vlek zraka, okoljski CO in tlak. Vsi merilni rezultati so na zaslonu vidni na prvi pogled in jih je mogoče individualno nastaviti, zahvaljujoč visokoresolucijskemu grafičnemu zaslonu.

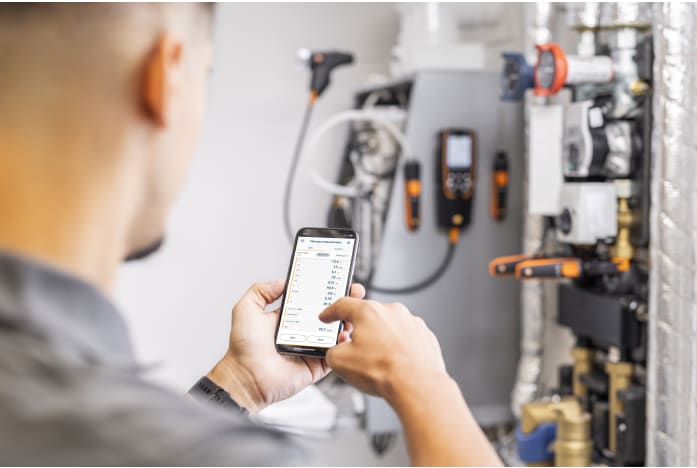

Po potrebi lahko med merjenjem obdržite proste roke - saj lahko analizator dimnih plinov testo 310 II pritrdite na kovinske površine, na primer na gorilnik, s pomočjo magnetov na zadnji strani instrumenta. Vendar to ni edina praktična funkcionalnost: Testo Smart aplikacija vam omogoča upravljanje in konfiguriranje instrumenta preko funkcije daljinskega upravljanja.

Robustna zasnova za zahtevna in umazana okolja, hitro kalibriranje senzorja v 30 sekundah, enostavno zamenljiv filter na sondo in hitro praznjenje kondenzacijske pasti omogočajo, da je analizator dimnih plinov odlično orodje za mehanike naprav, saj je pametno oblikovan.

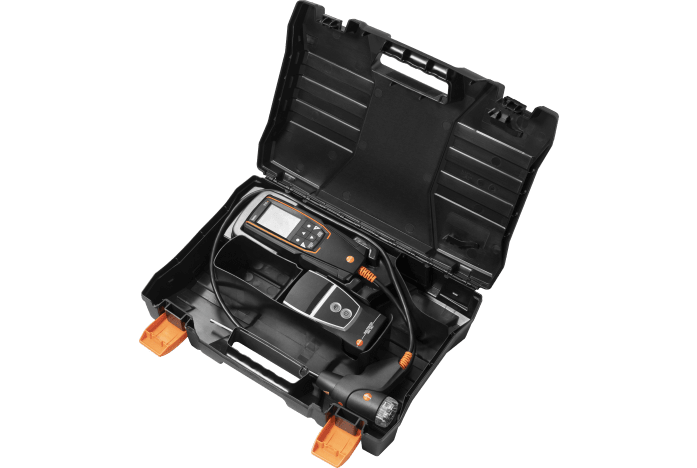

Po potrebi se merilni rezultati lahko prenesejo na dodatno dostopen Testo hitri tiskalnik prek vmesnika Bluetooth® ali pa se pošljejo po elektronski pošti in natisnejo neposredno na kraju samem.