- Home

- testo 350

testo 350 - Analysis Box for exhaust gas analysis systems

0632 3510

testo 350 - Analysis Box for exhaust gas analysis systems

0632 3510Designed as a two-part system, the testo 350 consists of the Control Unit (sold separately) and the Analysis Box. The Analysis Box houses all gas sensors and electronics, ensuring accurate data collection and analysis. It features a sealed, impact-resistant housing, making it durable and reliable for industrial field applications. An automatic extended measurement range ensures that the analyser can handle high gas concentrations without sensor overload by activating a dilution function when needed. Additionally, a service access port allows for easy maintenance and quick replacement of pumps, filters, and other wearing parts.

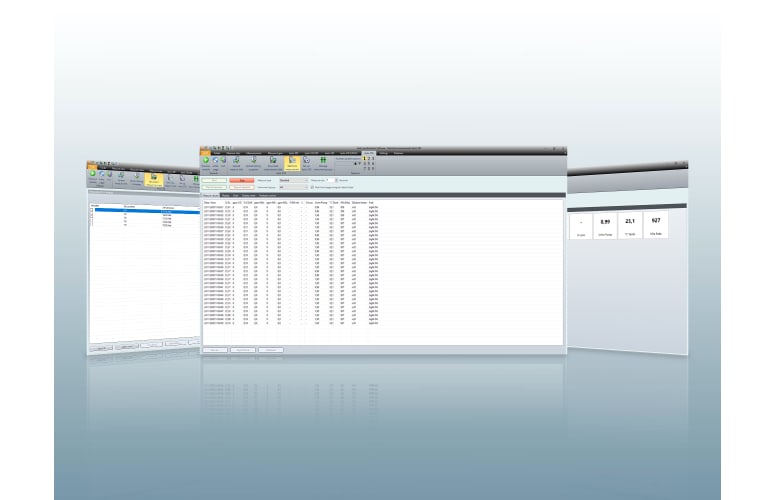

For added flexibility, the testo 350 Analysis Box can be controlled via USB, Bluetooth 2.0, or CANCase, allowing seamless integration with PCs and industrial monitoring systems. The testo easyEmission software enhances data management capabilities, enabling users to easily store, transfer, and analyse emissions data. The Analysis Box is also capable of performing standalone measurements, storing results internally for later retrieval.

The testo 350 is specifically tailored for industrial emission applications, including monitoring exhaust gas on industrial motors, burners, gas turbines, and thermal processes. With its advanced features, rugged durability, and MCERTS certification, it is the ideal solution for professional exhaust gas and emissions monitoring.

For leasing options and additional accessories, contact us today.

Please note: The testo 350 analyzer unit can only be used in combination with the testo 350 Control Unit or the "easyEmission" software. These items are available separately.

Temperature - NTC

| Measuring range | -20 to +50 °C |

|---|---|

| Accuracy | ±0.2 °C (-10 to +50 °C) |

| Resolution | 0.1 °C (-20 to +50 °C) |

| Ambient temperature probe | |

Temperature - TC Type K (NiCr-Ni)

| Measuring range | -200 to +1370 °C |

|---|---|

| Accuracy | ±1 °C (-200 to -100.1 °C) ±1 °C (200.1 to +1370 °C) ±0.4 °C (-100 to +200 °C) |

| Resolution | 0.1 °C (-200 to +1370 °C) |

Temperature - TC Type S (Pt10Rh-Pt)

| Measuring range | 0 to +1760 °C |

|---|---|

| Accuracy | ±1 °C (0 to +1760 °C) |

| Resolution | 0.1 °C (0 to +1760 °C) |

Flue gas probes

0600 9766

0600 9767

0600 8764

Pitot tubes

0635 2145

0635 2045

0635 2345

Temperature probes

0600 9797

0600 9787

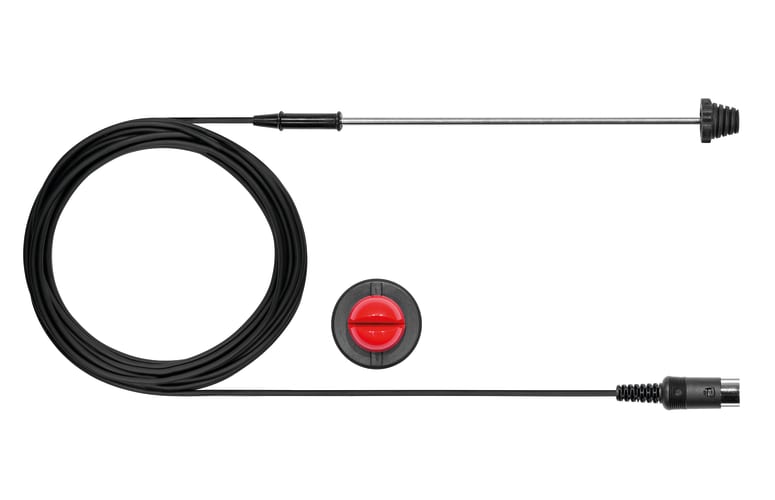

Accessories

0554 3334

0632 3511

0554 0549

Service measurement on gas turbines

Gas turbines are subject to flue gas limit values which are to be adhered to during operation and regularly checked depending on the size of the system. After commissioning and maintenance work, the system's emission values are checked for adherence to limit values and also the manufacturer's specifications, and documented if necessary.

Due to the low NO concentrations, emission measurements during inspection and adjustment work on LowNOx gas turbines need to be extremely accurate. The portable flue gas analyzer testo 350 featuring the combination of NO2 sensor and special NOlow sensor with a resolution of 0.1 ppm enables precisely these requirements to be met. In addition, the integrated gas preparation and special flue gas probe with patented special hose provide protection against NO2 absorption and allow measured values to be compared, irrespective of date and ambient conditions.

Service measurement on industrial engines

The flue (exhaust) gas analyzer testo 350 is an important tool for adjusting a gas or diesel engine to optimum effect. The testo 350 is used, for example, during commissioning, at regular maintenance intervals, or for troubleshooting unstable operational processes. Exhaust gas measurement is necessary to adjust the engine to optimum operating parameters while complying with the limit value regulations in force - this often entails measurements being taken over several hours. In particular, the high and fluctuating proportion of NO2 in the engine exhaust gas makes the separate measurement of NO and NO2 necessary to provide a highly accurate indication of the real NOx value of the engine. The integrated gas preparation and the special exhaust gas probe for industrial engines with patented special hose provide protection against NO2 and SO2 absorption and allow measured values to be compared, irrespective of date and ambient conditions.

Service measurement on after treatment systems

Restrictive limit values necessitate the use of a portable flue/exhaust gas analyzer to reliably determine the exhaust gas parameters in front of and after the after treatment system. In addition to the regular inspections for mechanical damage and contamination, the flue gas measurement provides information about the efficiency and functional reliability of a system. The bus function of the flue gas analyzer testo 350 allows flue/exhaust gas to be measured simultaneously in front of and after an exhaust after treatment system; this enables fast and easy assessment of the system. Any system modifications can be obtained from the measurement protocol.

Analysis of the gas atmosphere (thermal processes)

The flue gas analysis is used for thermal process monitoring in process combustion systems, such as in continuous furnaces for the glass, ceramics and construction material sector, or in steel melting and hardening furnaces, etc. In processes of this kind, substances may pass from the product being processed into the flue gas, increasing the usual emissions produced by the combustion system;

vice versa, pollutants may pass from the gas and become part of the product being processed. The flue gas analyzer testo 350 can be used to pursue two main goals: monitoring of the process-related gas atmosphere to ensure the optimum quality of the processed products. The gas analysis provides information for process-related measures, such as the design of the furnace interior, flame control, fired product and furnace temperature, or the combustion air supply. At the same time, the gas analysis contributes to optimum operation of the system in terms of operating costs and safety.

Service measurement on industrial burners

For whichever purpose combustion systems are used, whether for heating, generating electrical power, steam or hot water, for the production or surface treatment of certain materials, or to incinerate waste and scrap materials, the best possible way of managing combustion and incineration definitely includes the right knowledge about the compositions of fuels and combustion air, and their relationship to one another. Even how they are combined is crucial. Mobile measuring technology allows all relevant gases to be analyzed and optimum combustion processes therefore to be achieved.

The purpose of using a portable flue gas analyzer is to test the environmentally sound operation of combustion systems and optimum utilisation of the system. This means that a combustion system can be adjusted to its optimum working range to enable it to meet or come within stipulated emission limit values, while achieving a maximum level of efficiency in terms of combustion. The accurate flue gas analyzer testo 350, suited to tough practical conditions, is not only used for commissioning purposes, but also for repeat gas analyses during operation.

Official emissions measurement (compliance testing)

In most countries, operation of all types of industrial plants (e.g. large power stations, steelworks. cement works, glass works, and chemical plants), and local authority facilities, right through to small production sites is subject to strict regulations governing exhaust gas emissions into the atmosphere. Suitable measures are be taken to ensure and regularly verify that the components defined as pollutants do not exceed certain limit values in the flue gas.

The flue gas analyzer testo 350 can be used to carry out a preliminary analysis before an official emissions reading, or, depending on the country and directive, the actual official compliance testing.

- Data sheet testo 350(pdf, 441.35 kB)

- UK Declaration of Conformity testo 350 analyzer box(pdf, 65.53 kB)

- Instruction manual testo 350(pdf, 3.39 MB)

- Instruction manual testo testo SO2low Sensor(pdf, 996.08 kB)

- Quickstart Guide testo 350(pdf, 1.3 MB)

- Instruction manual easyEmission(pdf, 2.36 MB)

- Firmware testo 350 - Analyzer Box(v1.31, 1.75 MB)If the firmware update does not start under Windows 8.1 or Windows 10, a new bootloader must be installed on the measuring device once.

A description and all necessary files can be found under the search term: Update-Kit / Bootloader - testo 350 Firmware Update Guide(pdf, 586.1 kB)

- Update-Kit / Bootloader(V1.22, 1.24 MB)(testo 330 LL | testo 330i | testo 350 Control Unit + Analysis Box | testo 320)

If the firmware update does not start under Windows 8.1 or Windows 10, a new bootloader must be installed on the measuring device once.