- Home

- testo 324 leakage measuring instrument

testo 324 leakage measuring instrument - Pressure/gas leak detector

Product no. 0632 3240

testo 324 leakage measuring instrument - Pressure/gas leak detector

Product no. 0632 3240Description

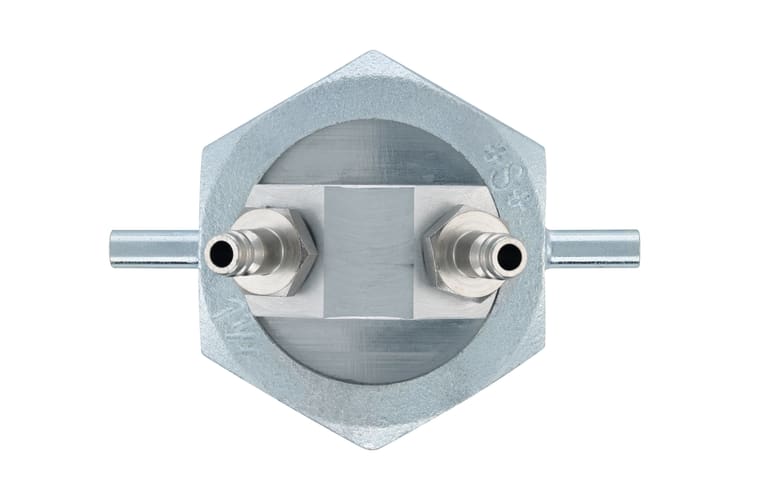

Pressure and leakage measuring instrument DVGW-approved for all tests at gas and water pipes as load and tightness test and serviceability test

Delivery Scope

Technical data

Temperature - NTC

| Measuring range | -4° to 212 °F / -20 to +100 °C |

|---|---|

Temperature - Type K TC

| Measuring range | -40° to 1112 °F / -40 to +600 °C |

|---|---|

| Accuracy | ±0.9 °F or ±0.5 % |

Absolute Pressure

| Measuring range | 240 to 460 InH₂O / 600 to 1150 hPa |

|---|---|

| Accuracy | ±1 InH₂O / ±3 hPa |

| Overload | to 480 InH₂O / to 1200 hPa |

Probe

Probes

0430 0143

0604 0194

0638 1748

Accessories

Additional accessories

0430 0143

0449 0047

0554 0532

Cases

0516 3121

0516 3240

Plugs, caps, hoses etc.

0554 3151

0554 3155

0554 3156

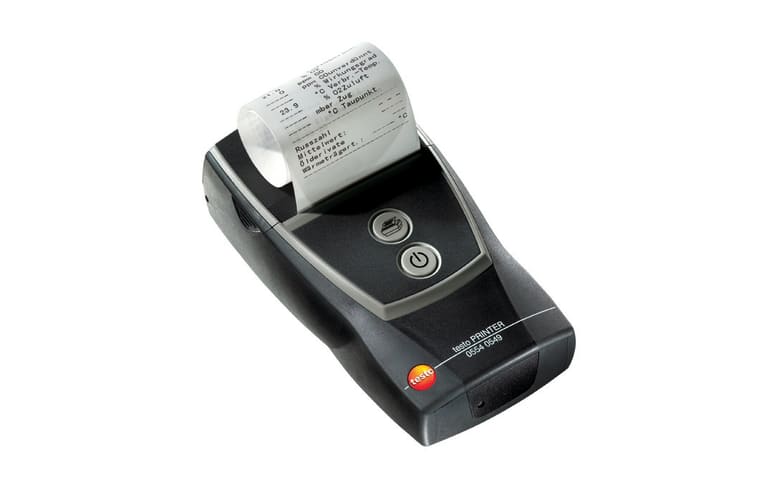

Printer and accessories

0554 0549

0554 0568

Applications

Leakage test on gas pipes (leak and load test)

Load testing

During testing, the material is tested for stability and the connections for service life; this takes place prior to plastering over or concealment of the gas pipes. During load testing, the newly installed pipe, without fittings or gas appliances, is put under 1 bar pressure. The testing medium is air or inert gas. There must not be a drop in pressure during the test, which lasts at least 10 minutes.

Leak test

This test is for checking the pipe for leaks, without fittings and gas appliances. The measuring instrument must not register a drop in pressure during the minimum 10 minute testing period (depending on the system volume); the test pressure is 150 mbar (previously 110 mbar).

Leakage test on gas pipes in the boiler room

Measuring pressure on burners (nozzle pressure, gas flow pressure, etc.)

Standard readings taken during services of domestic heating systems include checking the gas pressure on the burners. This involves measuring the gas flow pressure and gas resting pressure. The flow pressure, also called supplied pressure, refers to the gas pressure of the flowing gas and resting pressure of the static gas. If the flow pressure for gas boilers is slightly outside the 18 to 25 mbar range, adjustments must not be made and the boiler must not be put into operation. If put into operation nonetheless, the burner will not be able to function properly, and explosions will occur when setting the flame and ultimately malfunctions; the burner will therefore fail and the heating system will shut down.

Measuring pressure and leakage on water pipes

The testo 324 has been developed for professional applications in everyday work on water pipes. All relevant elements for the measurement are combined in one instrument.

Downloads

Product brochures

- Product brochure testo 324(pdf, 717.03 kB)

Operating instructions

- EU declaration of conformity testo 324(pdf, 33.59 kB)

- Instruction manual testo 324(pdf, 1.73 MB)

Software

- Firmware update testo 324(v.1.24, 12.27 MB)

- Instruction manual EasyHeat software(pdf, 3.55 MB)