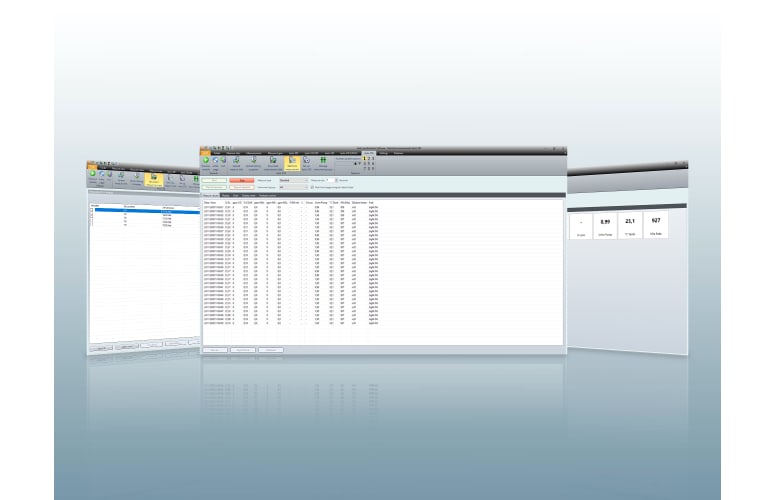

Everyone wants the highest efficiency, but on-site condition and environmental permits often contradict one another. In addition, dropping emissions limits (approaching 5 ppm total NOx in some areas) have been the driving factor for combustion maintenance and new installations. The testo 340 will provide the accurate measurements that are so necessary for environmental or process control.

Often when evaluating the burner’s characteristics, the focus of attention is on fuel, and air delivery, flame behavior, and of course the measured flue gas and emissions values. But, experienced service engineers also know that other combustion systems need to be checked:

- Optimized fuel density and delivery and air supply is crucial in order to maintain a wide operating range, stable flame, and the best efficiency with lowest emissions.

- Correct set-points must be confirmed. Ensure that fan capacity, the blowers and air ducts are controlled and coordinated with one another. These items combined with well-designed furnace dimension, burner spacing, and wind-box, all contribute to better controlled combustion.

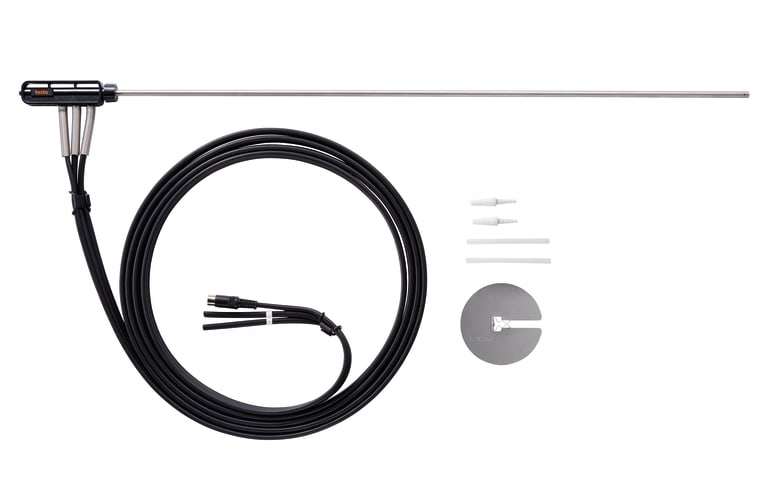

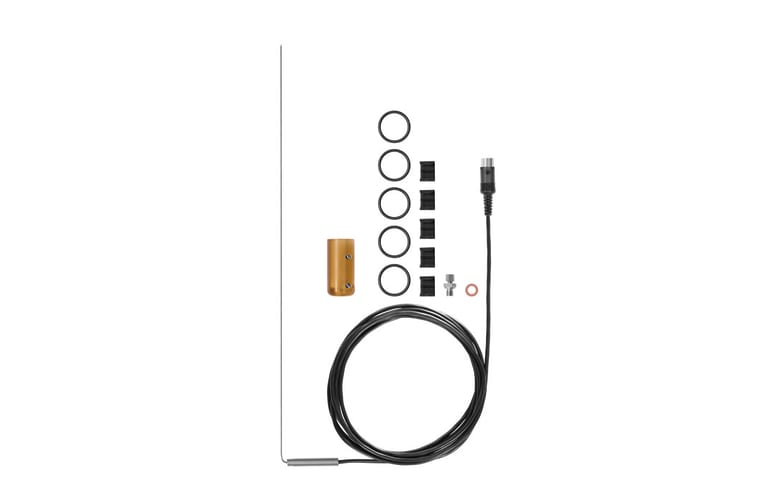

- Your tools and combustion analyzer need to work correctly all the time. You want to be certain the installation is operating correctly so use the Testo 340 to be sure!