The testo 350 Boiler and Burner Kit is a rugged emissions and combustion analyzer that is configured specifically for testing boilers and burners in industrial and commercial application. It has specialized components that make it ideal for boiler tuning, or for testing for US EPA MACT requirements and other state testing for NOx or CO compliance.

This 350 Boiler and Burner Kit will allow you to monitor the combustion parameters and optimize fuel consumption or tune your pollution control systems. It's the perfect analyzer for combustion analysis on boilers, burners, process heaters, dryers, furnaces, SCRs. The testo 350 can also be configured for gas turbines, IC engines, and other thermal processes.

The testo 350 portable analyzer system

The Control Unit is one way is used to control the analyzer and display the measurements. Turn it on and select the “Burner” icon. The analyzer will automatically guide you through the measurement. Save each reading or let the automatic program take over and data log automatically. Use one of the default programs, use your own program, or use the EPA CTM-034 default program for hands-free testing. The Control Unit and analyzer box include wireless Bluetooth connectivity up to about 330 feet distance. The magnets on the Control Unit allow you to see the readings at the combustion controls via USB to the laptop at a safer and more convenient location.

The Analyzer Box (contains the sensors, pumps, power, etc.) The Bluetooth connection allows the analyzer to be close to the stack and displaying the combustion parameter up to 330 feet away. By being close, shorter sample lines are used. This results in response times faster than any other portable analyzer in the market. It allows you to make accurate adjustments when the combustion changes with essentially no time lag. It saves you time, money and the hassle of carrying and cleaning long sample lines.

The 350 uses an advanced sample gas path and sample conditioning system. The pump pulls a high velocity sample through Teflon sample lines and monitors flow and automatically adjusts to maintain a constant flow rate. A specially designed gas path uses a Peltier chiller system to continuously remove moisture which satisfies EPA compliance and additionally protects the sensors. These state-of-the-art components combined with advanced temperature compensation and other data process handling techniques result in highly accurate measurements from high range down to single digit PPMs. Especially important for today's low NOx boilers and burners.

With these components, this kit also complies with the following EPA and state test methods:

- EPA 7E, EPA CTM -030

- ASTM-D6522

- California - SCAQMD 1146, SCAQMD 1146.2

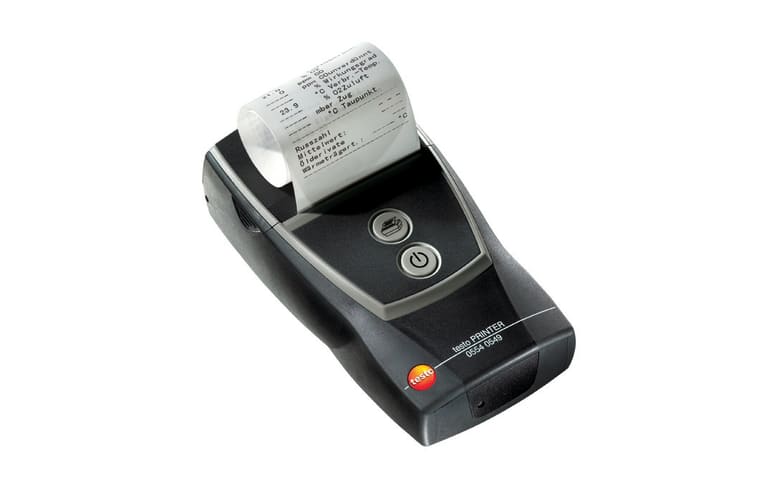

Communications & Software The Analysis Box can be controlled by the Control Unit or operated using easyEmission or TECsoft software options, It can connect via USB, Bluetooth® 2.0, or directly connected to the PC or notebook. The testo 350 can even be daisy-chained into a multi-analyzer configuration to monitor multi-points simultaneous with up to 16 analyzer boxes. Perfect for testing multi-port SCRs or pre and post-catalyst testing. See the Applications tab for more information on multi-analyzer testing.

testo 350 benefits for Boiler and Burner applications

Control Unit has wireless Bluetooth control (to 330 feet). It displays the combustion parameters at the control panel, increases response time by reducing sample hose length and gets the job done faster.

The variable output sample pump adjusts to in-stack conditions (high draft or high particulate loading)

CO sensor protection - when a high concentration is detected, the CO purge will activate and the other sensors continue to measure, therefore no reason to stop testing or tuning.

Integrated gas conditioning removes condensate from sample which will protect sensors and delivers more accurate dry basis data as required by EPA.Testo 350 Boiler and Burner Kit includes

- testo 350 Control Unit

- testo 350 Analyzer Box

- Sensors in Kit: O2, CO, NO, NO2 (or optional Low NOx or Low CO options with 0.1 PPM accuracy)

- Bluetooth 2.0 communication (to 330 feet away)

- Thermoelectric sample conditioner with condensate removal pump

- USB connection

- AC power cable

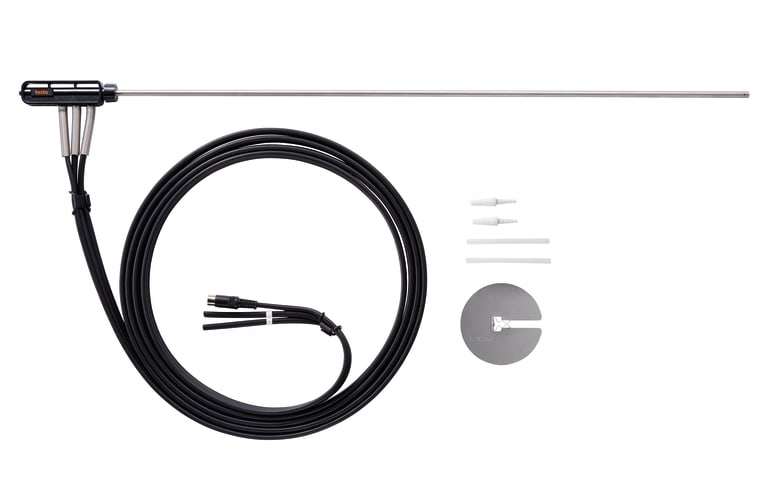

- 13" sampling probe (932 °F max) with 7' hose

- Extra particle filters

- 6' data bus communication cable

- EasyEmission software

- Rugged case