Data monitoring in harmony.

With the fully automated and integrated monitoring system testo Saveris 1.

Monitoring in harmony? Performance optimized!

In the process landscapes of leading companies, one aspect is of crucial importance: environmental monitoring.

The key to achieving optimum performance in the monitoring of quality-relevant measured values lies in efficiency, reliability and comprehensive control. The complete solution testo Saveris 1 meets precisely these requirements.

The proven monitoring system combines the best of three worlds: advanced software, secure hardware and customized service. Safety and performance are in perfect harmony.

testo Saveris 1 is your reliable partner for outstanding performance in environmental monitoring, process optimization and compliance.

Read five exciting stories from our customers on this page and find out what this means in concrete terms.

5 stories – 1 solution: How testo Saveris 1 convinces in use

When it comes to environmental monitoring, companies are constantly faced with complex challenges: inadequate WLAN coverage, limitations in the technical equipment available to teams, the need for seamless calibration and integration of different measurement systems, and the need for customized consulting services. These scenarios require well thought-out solutions.

How can we at Testo meet these diverse requirements without us or our customers having to compromise on quality and safety? Here, five success stories show how testo Saveris 1 overcomes these challenges and improves efficiency and reliability in different environments.

What to do if there is insufficient WLAN coverage

How can employees be alerted about limit violations without SMS and e-mail?

How to avoid measurement gaps during calibration

Is it possible to display measured values from different sources on one dashboard?

Which support services can Testo offer companies in the field of environmental monitoring?

A long-standing customer maintains its laboratories in a historic industrial building with impressive and unique architecture. But this aesthetic brings a significant problem with it: The historic building structure with extremely thick walls and a nested floor plan makes it almost impossible to achieve seamless WLAN coverage. This challenge not only affected the researchers' daily work, but also raised questions about data security and integrity.

Our task was clearly defined: We had to implement a reliable monitoring system that was capable of ensuring continuous and secure data transmissions despite the adverse structural conditions.

The solution was the modular data logger concept of testo Saveris 1, which allowed our customer to choose between WLAN, radio and Ethernet. In this way, it was possible to switch to other transmission technologies when the WLAN signal was weak, enabling continuous and seamless monitoring of critical data.

The employees in the laboratory of a leading chemical company were unable to carry their company hardware with them at all times, which made it difficult to communicate alarms via email or text message in the event of limit violations. This led to delays in response and potential risks in the process.

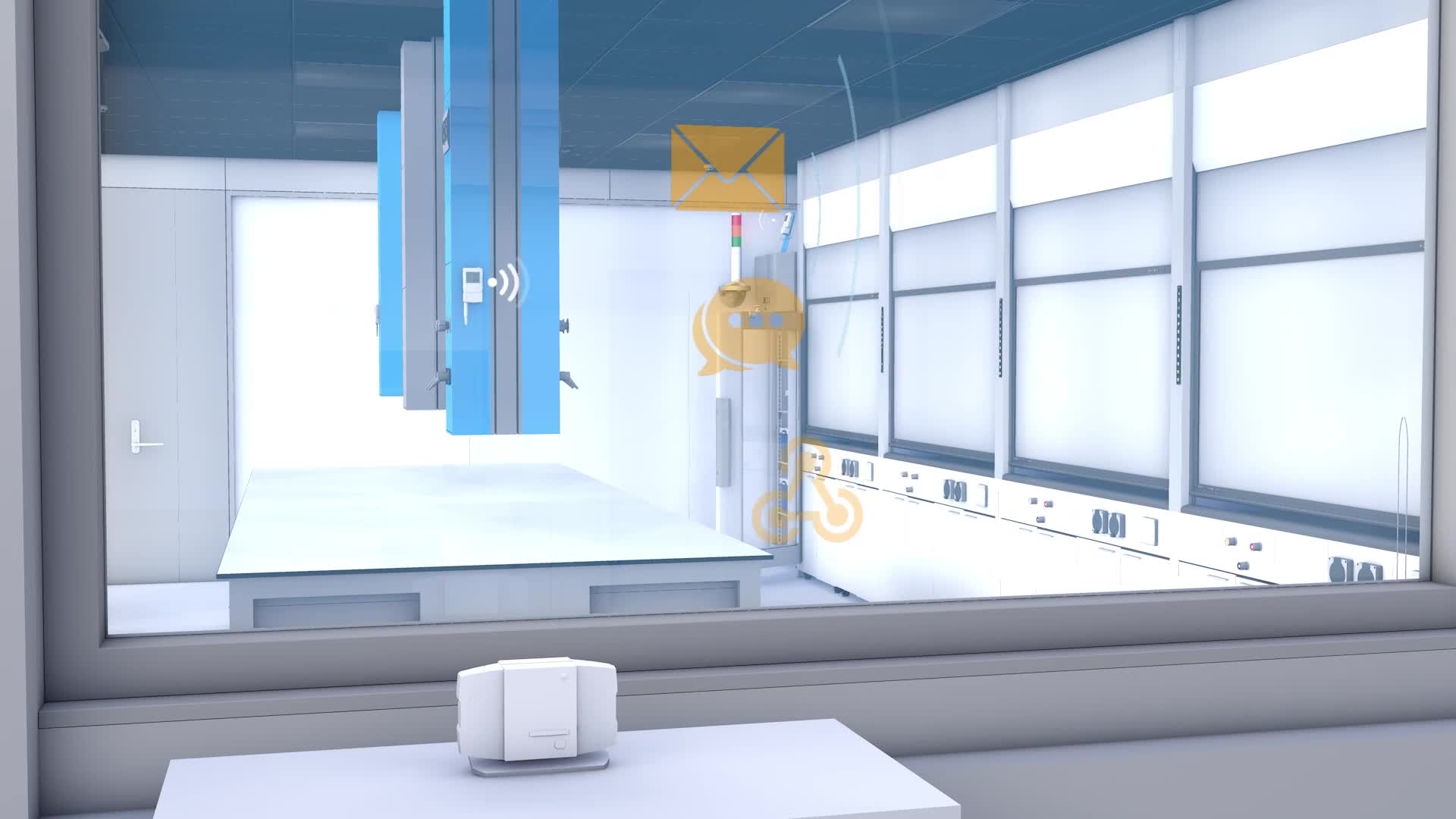

The solution was the innovative alarm function via webhooks, which activates a signal light in the laboratory. As soon as a parameter falls outside the permissible range, the signal lamp lights up and immediately signals to the teams that there was a problem. In addition, the company installed a central screen showing the floor plan-based cockpit of the testo Saveris 1 software. This enabled employees to see the exact position and status of each measuring point.

These adjustments made it possible for employees to be constantly informed about the current status of the measuring points and to react quickly to critical situations, even without their own company devices. By introducing the decentralized alarm function and the cockpit display, the company was able to significantly improve safety and efficiency in the laboratory.

In the ultra-modern warehouse of a customer in the logistics sector, those responsible were faced with a crucial challenge: ensuring seamless monitoring and documentation, even during the calibration phases of the sensors. Traditionally, calibration of the analog sensors led to interruptions, which posed a problem for continuous quality control and stock monitoring.

The innovative solution came in the form of testo Saveris 1 digital sensors. Our customer equipped its warehouse with this advanced technology, which enabled the sensors to be calibrated separately from the data logger. This meant that sensors in need of calibration could be easily replaced with spare sensors without interrupting data recording.

By switching to digital sensors, the company not only eliminated measurement gaps during calibration times, but also increased the overall efficiency and accuracy of its warehouse monitoring. The changeover proved to be a crucial step in maintaining standard-compliant documentation, which is essential for meeting the strict quality and safety standards in warehousing.

An industry leader in the pharmaceutical industry wanted a clearer overview of various measurement parameters from different sources. The complex data landscape made it difficult for the team to react quickly to changes and gain comprehensive insights.

The introduction of Testo's innovative Rest API has ushered in a transformative change. This enabled seamless integration with the testo Saveris server, allowing measurement and system data to be retrieved and processed effectively. By using this solution, the company was able to develop a centralized dashboard that not only brought together various data streams, but also connected them to other important operational information in a meaningful way.

The redesigned dashboard provided the company with unprecedented insight into its operations, improved responsiveness and optimized monitoring of plant performance.

An up-and-coming biotechnology company was confronted with a variety of technical requirements and support needs. The diversity of the projects and the complexity of the technologies used required a flexible yet robust support solution.

In this situation, the team discovered Testo's diverse helpdesk packages. The packages on offer range from solid basics in the basic package to comprehensive all-round support in the premium package. This flexibility allowed the company to choose a customized service solution that was precisely tailored to its specific needs and challenges.

By opting for the Advanced package, which offers a fast response time and an extended scope of support, those responsible were able to significantly increase the efficiency of their research and development work. The availability of extended support services helped to resolve technical issues faster and minimize downtime, ultimately driving our client's productivity and innovation.

Testo's helpdesk packages, our customer not only found the ideal support for their current needs, but also secured the possibility of adapting the support in the event of future changes or expansions to their business activities.

Testo North America also offers additional services, including but not limited to: System Validation, Audit Prep support, On-Site Interventions, Advanced User Training, SOP support, On-Site Hot Swap Service and Regular System Diagnostics/Reviews.

What you need to know – downloads with tips and background information

Here you will find valuable expert knowledge to help you optimize your measurements and enhance your skills. Whether you're a beginner or a professional – our carefully selected content provides you with easy-to-understand and practice-based support.

Checklist: Find your monitoring system

Are you looking for the perfect measurement data monitoring system that is precisely tailored to your requirements? Our comprehensive checklist will help you navigate through the multitude of options available to find the ideal system for your needs. This precisely compiled list takes into account all critical factors from technical specifications to user-friendliness, security standards and integration options. Whether for industrial applications, research purposes or quality monitoring – our checklist ensures that you make an informed decision and choose a system that guarantees efficiency, precision and reliability.