- External thermocouple parallel connections compatible with a variety of different probes

- Data transfer possible using the USB port, or SD card (optional)

- Rugged metal housing makes it ideal for use in extremely cold or dusty environments

- IP54 protection class

- Capable of CFR 21 Part 11 Compliancy

- Free data logger software available for download

- Data is secured within the logger, and can be password protected using ComSoft

- Home

- testo 176T3

testo 176T3 - Four-channel temperature data logger.

Product no. 0572 1763

testo 176T3 - Four-channel temperature data logger.

Product no. 0572 1763 Professional software with Excel export function for programming the logger and data analysis.

Professional software with Excel export function for programming the logger and data analysis.

Description

Delivery Scope

Technical data

Temperature - Type K TC

| Measuring range | -328° to 1832 °F / -200 to +1000 °C |

|---|---|

| Accuracy | ±1 % of mv (-328° to -148.2 °F) ±1 Digit / ±1 % of mv (-200 to -100.1 °C) ±1 Digit ±0.5 % of mv (158° to 1832 °F) ±1 Digit / ±0.5 % of mv (+70.1 to +1000 °C) ±1 Digit ±0.5 °F (-148° to 158 °F) ±1 Digit / ±0.3 °C (-100 to +70 °C) ±1 Digit |

| Resolution | 0.1 °F / 0.1 °C |

Temperature - TC Type T (Cu-CuNi)

| Measuring range | -328° to 752 °F / -200 to +400 °C |

|---|---|

| Accuracy | ±1 % of mv (-328° to -148.2 °F) ±1 Digit / ±1 % of mv (-200 to -100.1 °C) ±1 Digit ±0.5 % of mv (158.2° to 752 °F) ±1 Digit / ±0.5 % of mv (+70.1 to +400 °C) ±1 Digit ±0.5 °F (-148° to 158 °F) ±1 Digit / ±0.3 °C (-100 to +70 °C) ±1 Digit |

| Resolution | 0.1 °F / 0.1 °C |

Temperature - Type J TC

| Measuring range | -148° to 1382 °F / -100 to +750 °C |

|---|---|

| Accuracy | ±0.5 % of mv (158.2° to 1382 °F) ±1 Digit / ±0.5 % of mv (+70.1 to +750 °C) ±1 Digit ±0.5 % of mv (+158.2° to 1382 °F) ±1 Digit / ±0.5 % of mv (+70.1 to +750 °C) ±1 Digit ±0.5 °F (-148° to 158 °F) ±1 Digit / ±0.3 °C (-100 to +70 °C) ±1 Digit |

| Resolution | 0.1 °F / 0.1 °C |

Probe

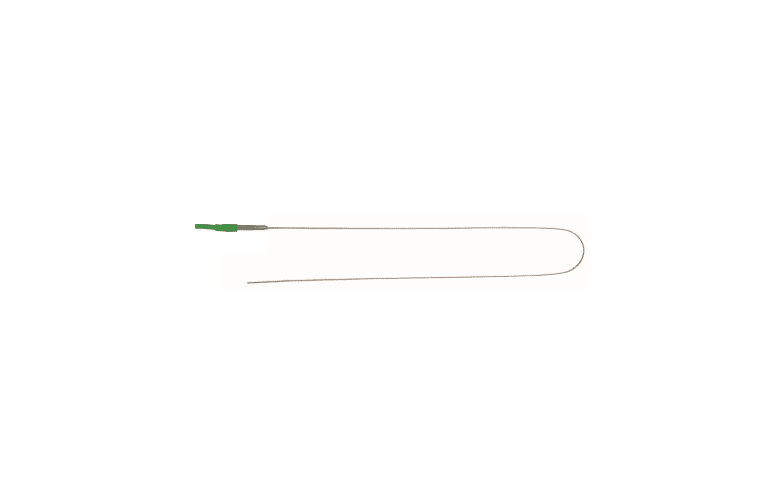

Air Probes

0602 1793

0603 1793

Food Probe

0602 2292

0603 0646

0603 2192

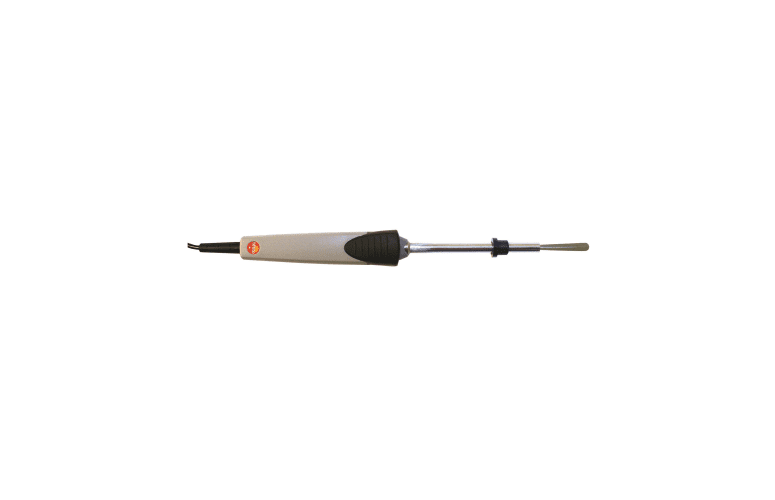

Immersion / Penetration Probe

0602 0493

0602 0593

0602 1293

Surface probes

0602 0092

0602 0193

0602 0393

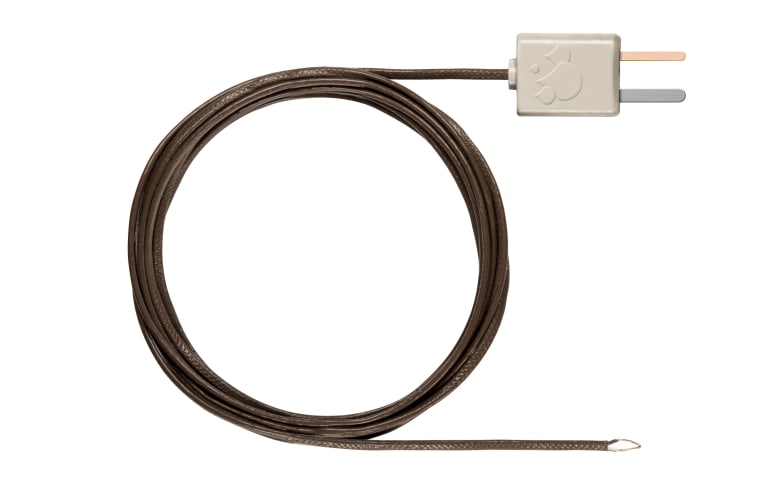

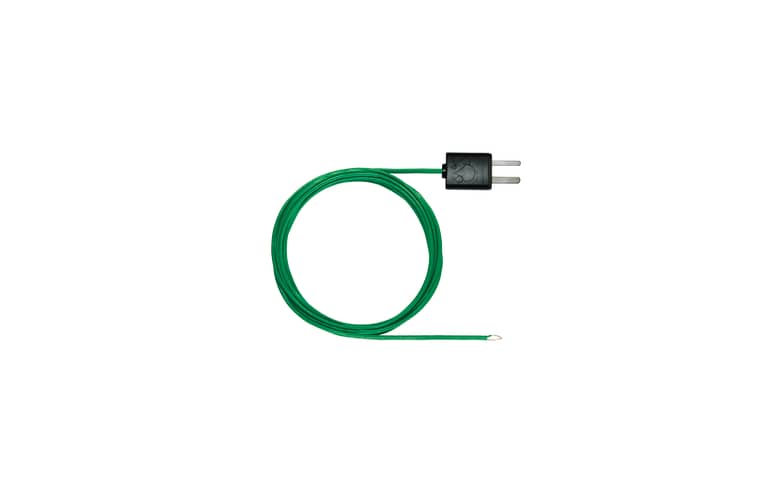

Thermocouples

0602 0644

0602 0645

0602 0646

Accessories

Accessories

0449 0047

0515 1760

0554 1703

Applications

Checking the temperature in super freezers or under cryogenic conditions

Specific products must be stored under extremely cold conditions so as to ensure their quality. Therefore, in many laboratories and research facilities you can for instance find super freezers which can be cooled down to -80 °C using liquid nitrogen or dry ice.

In many cases storage under cryogenic conditions is even required. So, particular biological or blood products are for example stored and transported at -196 °C. Special measuring instruments, which are also fit for purpose at such low temperatures, are needed to check these extreme conditions.

Monitoring process temperatures

For production quality assurance, the temperature must frequently be checked at various points in production processes. Whether it is the air temperature, the temperature of production items themselves or the surface temperature of machines or motors.

Using thermocouple probes, data loggers can also record data in the kinds of extreme temperature ranges that are often to be found in production processes. The probe's fast speed of response contributes here to a good measurement result being achieved even in processes where temperatures change quickly.

Checking the flow and return temperature of heating systems

The heating period starts in autumn and with it the time for tenants to complain that the apartment cannot be heated to the extent they want as well. Using flexible external pipe wrap probes, you can for instance check the flow and return temperature of individual heaters in a targeted way, so as to identify causes and remedy them.

Downloads

Product brochures

- Data sheet testo 176 T3 / testo 176 T4(pdf, 657.28 kB)

Operating instructions

- EU declaration of conformity testo 176 T3(pdf, 33.21 kB)

- Instruction manual testo 176(pdf, 4.46 MB)

Software

- Firmware testo 176 T3(v2.01, 4.13 MB)

- testo usb driver - Instruction manual(pdf, 676.7 kB)

- ComSoft Basic Instruction manual(pdf, 868.78 kB)

- testo usb driver - for various measuring instruments(v2.9.1, 2.02 MB)USB driver for the following devices with USB port: * USB Interface testo 174 / 177 - T + H * testo 300 / 320 / 330 / 330i / 335 / 340 / 350 * testo 435 * testo 556 / 560 / 570 / 580 * testo 635 * testo 735 * testo 845